Sheet metal bending is an act that requires creativity and some level of accuracy to get the right shape to fit its use. Sheet metals are used for various purposes, such as car antibodies, building truck beds, etc. Some homeowners use steel metal for perimeter fencing around their houses or yard. As rewarding as sheet metal bending is, it can also frustrate you if you don’t get the necessary shape.

Whether you are a recreational metal worker or you want to get your sheet metal shaped DIY, the machine to bend sheet metal may not be accessible for you. And one of the most useful tools to bend a sheet is the brake. Without the brake or other bending machine, how to bend sheet metal can be worrisome.

However, a metal hand bender can finish the work if you want to bend sheet metal at home through the DIY project. This article will guide you through bending sheet metal without a brake.

What is a sheet metal bender brake?

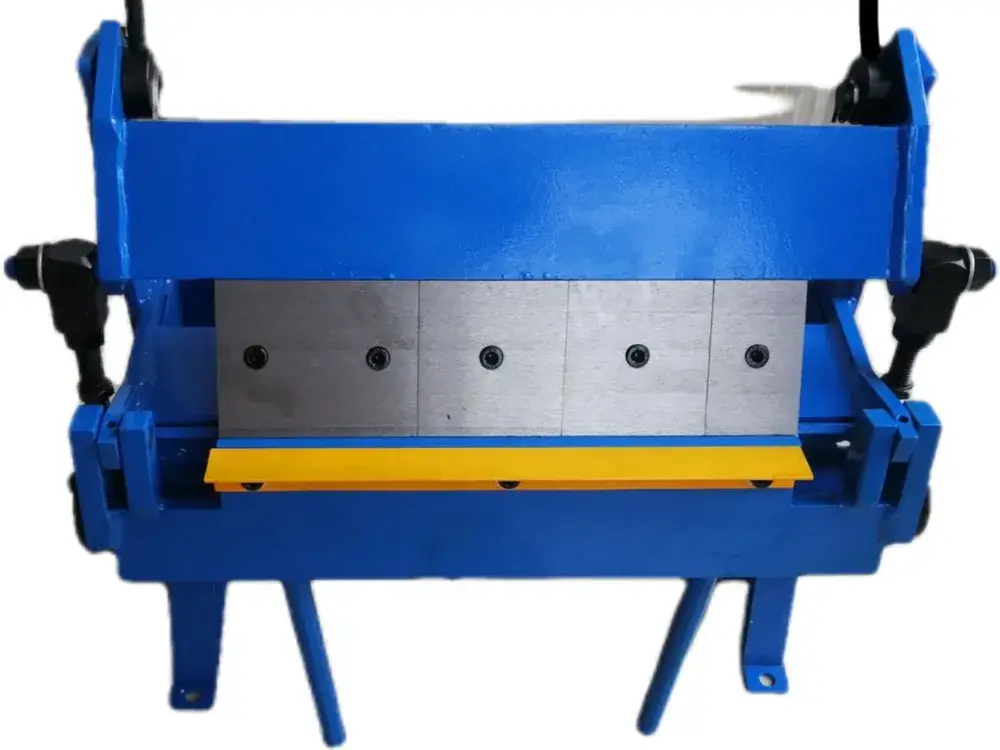

A brake in sheet metal bending is a machine used for metal works. With this tool, you can bend any metal sheet to any angle. In a metal shop, brakes are mounted at different angles where it will be easy to bend metals. Most brakes have automated arms that help in getting the bending done.

The brake used for bending sheet metal comes in different variants: cornice brake and box-and-pan brake. The cornice brake is meant to do simple bending and creases on sheet metal. With box-and-pan brake, box-and-pan shapes can be formed with it. Box-and-pan brake is a bending machine, bending brake, or sheet metal folder.

Tips for bending sheet metal without a brake

Sheet metals are easy to make use of in getting metal-related work done. With or without a sheet metal fabrication bend tool, you can achieve much with sheet metals. However, to have clean, accurate, and professional sheet metal bends, there are some tips you need to know and work with.

- Know the material suitable for bending: some sheet metal materials are more ductile than others. With this, some sheet metal will bend easily and give you the angle bending you want. Whereas metals that are not ductile can weaken and crack in bending. When handling less tensile materials, it is advisable to heat the workpiece. Doing this will help reduce the risk of the sheet metal material cracking in bending.

When you want to bend sheet metal, you will come across different sheet metal materials. Some are easy to maneuver without getting cracked or weakened, while some are not. Mild steel is easy to bend without any difficulty or heating before bending. Spring steel is another sheet metal that can bend to any shape. However, you will need to anneal it before you can get the angular bending. For materials such as annealed alloy steel, 6061 aluminum, bronze, and titanium, to bend them, you will need to heat them as they are not malleable. However, copper, 5052 aluminum, and brass easily bend to get the desired shape.

- Avoid bending to a sharp internal corner: when bending sheet metal, do not bend to a sharp inside corner to avoid putting internal stress on the material. Whether working with a malleable material or not, you need to avoid sharp inner corners so as not to crack the metal at the bend or weaken it to the point of breaking.

The best practice is to use a radius on the sheet metal bender tool to prevent cracking or weakening of the spots. For this, make the inside bend radius equal the thickness of the material you want to form.

- Use of bend allowance: To get the shape, bending sheet metal requires pushing, pulling, and stretching. As a result, calculating bend allowance will aid in getting more reliable numbers to work from laying out flat sheet metal. Some factors are to be considered in calculating the bend allowance, such as the material’s thickness, the internal radius’s size, and many more.

- Apply heat for thick or heavy bends: to bend sheet metal, you cannot easily bend some materials without getting cracked or weakened. For such material, it will require heating through annealing or hot forming. When you use annealing for materials that are not malleable, it becomes softened and malleable. You can use this method for materials such as carbon steel or aluminum. Using hot bending, you have to heat the material till it gets red and becomes bendable. The hot bending will help reduce the risk of cracking in most sheet metals.

- Protect the sheet metal surfaces: If care is not taken, the material’s surface can get scratched easily while bending sheet metal. To avoid scratching, you must protect the surface before you begin bending. One of the ways of doing this is to put masking tape on the surface that may likely have contact with the sheet metal bender hand tool.

If you perceive that the metal is being scratched, you should add more layers of masking tape to the surface or resolve to use wood blocks. With the wood blocks, you will sandwich the part you are bending with a mallet, and the surface of the metal will not be damaged as the wood will be soft on the metal.

Things required when bending sheet metal without a brake

Before proceeding to bend sheet metal without a brake, there are some things you will need to get the job done.

- The angle to bend the metal should be determined and marked on the protractor. With the protractor, you can gauge the level at which you want to bend the sheet metal. You also have to cut the section of the metal out or prepare the metal by getting rid of burrs or sharp edges that may affect the bending.

- Ensure that the angle iron is slid into the vise’s jaws for a flat lay of the metal to be bent.

- The sheet metal should be inserted into the vise’s jaws to make the metal head toward you while bending it.

- At this point, you want to have the bending, light butane torch there to warm the metal. Let the metal glow from red to orange to bend. Avoid it getting white.

- After heating the metal, hold the metal with pliers as the part you have heated cooling off. Pull it towards your position gently, which will make the metal bend. Do not force the bending if it cannot go further, reheat the metal and continue with the bend to get the shape you want.

How to bend sheet metal without a brake

Sheet metal bending brakes are machines that are only sometimes portable or affordable for harbor freight sheet metal benders. To bend sheet metal, there are other hand benders or minimum tools you can use in place of a brake. However, before you bend sheet metal, you should consider some things.

What is a good bend?

A good bend is achieved using a brake or sheet metal hand bender. Therefore, a good bend is derived by the sheet metal bend radius, i.e., how straight the radius angle is. The radius must be tight and sharp as possible as it can be because it is the determining factor of the bend. The radius of the sheet metal bend also has to do with the clamping material used for the bending.

To make a tight bend, a harder object like steel will be required because the inside radius of the bend is equivalent to the radius of the clamping material. Also, the outside radius is equivalent to the clamping material radius and the bent sheet metal thickness. For a 900 bend, a piece of angle steel with a sharp edge is ideal.

To bend sheet metal without a brake, mark where the bend will be. And to do this, draw a line on the sheet with a marker on the area you wish to bend. After that, clamp the sheet metal using a steel shape with a rectangular tube and rigid angle. This steel shape must be longer than the sheet metal you want to bend on both sides of the material. And it must line up with the edge of the marking. You use the clamping tool to hold down the metal on the two sides without interfering with the bend’s direction.

Methods of bending sheet metal without a brake

- Sheet metal hand bender: to bend sheet metal with the hand, ensure that the sheet metal is clamped tightly. Then, have a good grip on the metal material from the bottom, and push the sheet metal upward to refine and lower the position of the push to a point where you cannot push anymore. Unclamp the sheet metal and refine the bend with your hand to get the job well done.

- Bending with a hammer: bend sheet metal with a hammer also involves using the hand method. After you have pushed the metal upward with your hand, you give it a soft hammering on the bend. This will help in refining the edge for a tight edge.

- Score and bend: using this method to bend sheet metal, you need a flexible material that will give you joint scoring. Put the sheet metal on the flexible material, put a straight edge on it and clamp it down tightly. While doing this, leave enough frame between the line and the straight edge to accommodate the scoring tool. You can use a screwdriver for the scoring tool because it’s hard on steel metal. With the screwdriver, you will score the steel metal multiple times to have a weakened line where you want to bend the steel. Please turn to the other side of the steel metal and clamp it tightly. Push the bend forward as close as possible to get the bending angle and refine it to get an accurate bend.

- Bending with a roller: bend sheet metal with a roller requires making a tool with trolley wheels and timber. The type of trolley wheels suitable for this is either plastic or hard rubber wheel. They must be square on the edge and round in the middle to perform best. The two trolley wheels should be screwed to the timber.

Clamp the sheet metal and push it to the maximum it can go based on its thickness. Then, roll the roller on the bend as possible till you have a refined bending with a suitable radius.

Conclusion

If you do not have a brake available to bend sheet metal, other methods can also work fine for the intended purpose. However, the method you choose depends on the results you aim at. For instance, you can bend by hand if you don’t desire a sharp radius. You can use a hammer if you want it to be tightened and have time to refine the surface afterward. You can use the score and bend method to control a long-end bend. The roller method can be used if you work with a finished shape that will be used externally.

There are better methods to use for sheet bending. The situation and the metal’s purpose will dictate what to use. Any of the methods to use to bend sheet metal are without the brake.