sheet metal laser cutting price

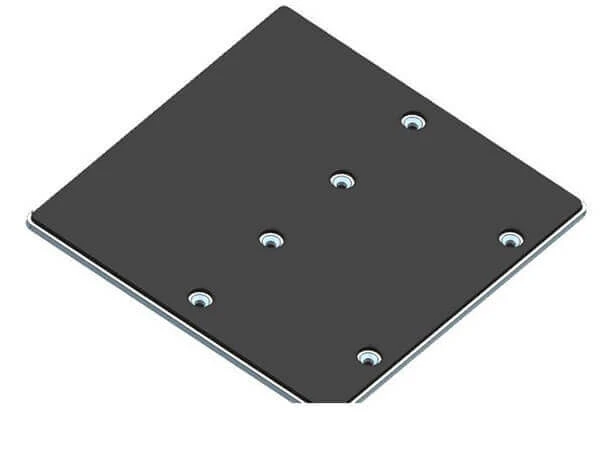

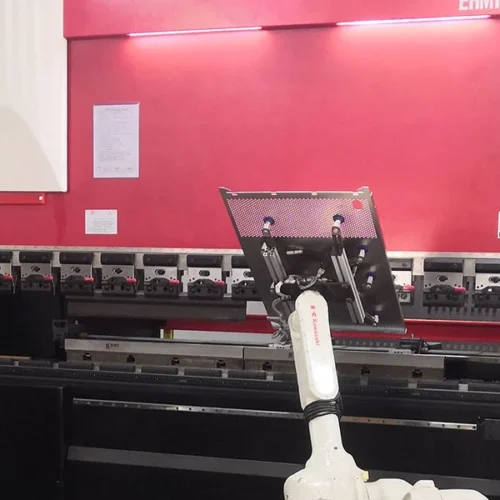

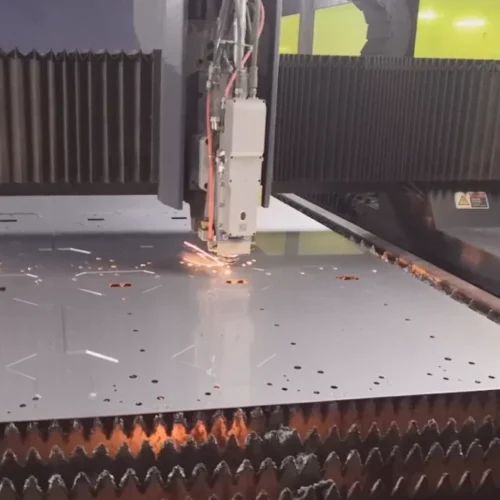

The laser cutting technique is popular due to its high efficiency and saving of materials. It can cut sheet metal, wood, plastic, etc. Shengen, the leading China laser cutting supplier, delivers the best sheet metal laser cutting service. When it comes to sheet metal laser cutting, the first one that comes to mind is the cost. Sheet metal laser cutting cost is affected by three factors: materials, thickness, and structure of products.

Materials

Steel

Steel is one of the most popular metals in the industry. It was used in every field, such as aerospace, manufacturing, construction, and automotive industries. We can deliver laser cutting services, whether stainless steel, carbon steel, alloy steel, or tool steel.

Aluminum

Aluminum is also commonly applied in all industries, such as construction, automotive, and home design. However, aluminum is one of the most difficult materials to cut. That is because of the unique properties of aluminum. Aluminum’s reflectivity, molecular structure, and thermal conductivity make it hard to do laser cutting. However, this doesn’t mean we can’t do aluminum laser cutting. We have been improving our aluminum laser cutting. We have formed a mature process to deal with aluminum sheet metal.

Titanium

Titanium is less widely used than steel and aluminum. But it is essential for some fields, such as aerospace and military. Owing to its high strength, anti-corrosion, and good heat resistance, it has been a material that other materials can not replace.

Though there is no so big demand for laser cutting titanium, we still insist on delivering titanium laser cutting services for our clients. We can provide the corresponding service if you need cut steel, aluminum, or titanium.

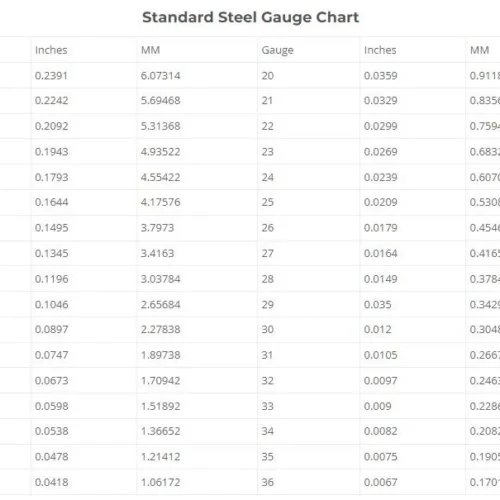

Thickness

Although sheet metal laser cutting is economical and efficient, there is a common rule, that is, it’s more difficult to cut thick material, which means cutting thicker sheet metal will cost more. Usually, we can deliver 0.3mm to 10mm sheet metal laser cutting. But it differs owing metals. For example, we can cut the 0.3mm to 2.5mm pre-galvanized or Zintec steel and the 0.3 mm to 10mm carbon steel. Even if the laser cutting capacity has increased, carbon steel’s laser cutting thickness is up to 20mm. It is advised that choose other sheet metal cutting methods for cutting thick metal.