What is Metal Powder Coating?

Powder plays an essential role in various items and accounts for about 15% of the market for industrial finishing. Since it was first used as a dry finishing process in North America in the 1960s, powder coating has experienced enormous growth in acceptance. For a high-quality, long-lasting finish, more and more businesses specify metal powder coatings, which enable increased production, better efficiency, and easier environmental compliance. Metal powder coatings are used as functional (protective) and ornamental finishes and come in various colors and textures. Additionally, thanks to technological improvements, they now offer outstanding performance characteristics.

How does metal powder coating work?

Flow modifiers, leveling agents, pigments, and other additives are coupled with polymer resin systems to create metal powder coatings. These ingredients are melted, cooled, and then milled into a consistent powder like baking flour.

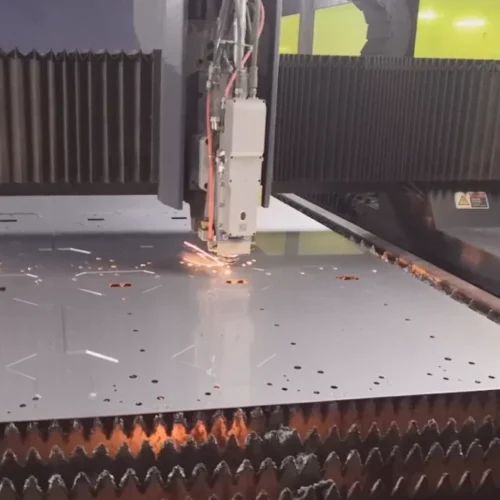

The process known as electrostatic spray deposition is frequently used to apply the powder coating on a metal substrate.

The powder particles in this application method are given an electrostatic charge by a spray pistol, which attracts them to the grounded side.

The components are put in a curing oven after the metal powder coating has been applied. The heat causes the coating to chemically react, resulting in long molecular chains and a high cross-link density.

The molecular chains in question are tough to break. The most typical way to apply powders is using this kind of application. Additionally, non-metallic substrates like plastic and medium-density fiberboard can receive powder coatings.

Occasionally, a fluidized bed application includes the application of a powder coating. Metal powder coatings are simple to use, cost-effective, ecologically friendly, and durable regardless of application.

The coating melts and drips over the part when hot parts are dipped in a hopper of liquidizing powder. Post-cure might be necessary, depending on the part’s bulk, the temperature, and the kind of powder employed.

Each day, you come into contact with thousands of products that have a powder-coating finish.

Persistence of Metal Powder Coating

Metal powder coating protects the most demanding, durable gear and the typical home items you rely on. It still produces a pleasing appearance but provides a more lasting surface than liquid paints.

Impact, moisture, chemicals, ultraviolet light, and other harsh weather conditions affect the coating quality of powder-coated products differently than they do on different types of coated products. Dings, chips, abrasions, corrosion, fading, and other wear-related issues are less likely.

It’s hard. It looks fantastic. It also lasts a very, very long period. Due to its durability and favorable environmental effects, metal powder coating is a desirable option.