What is rubber coating?

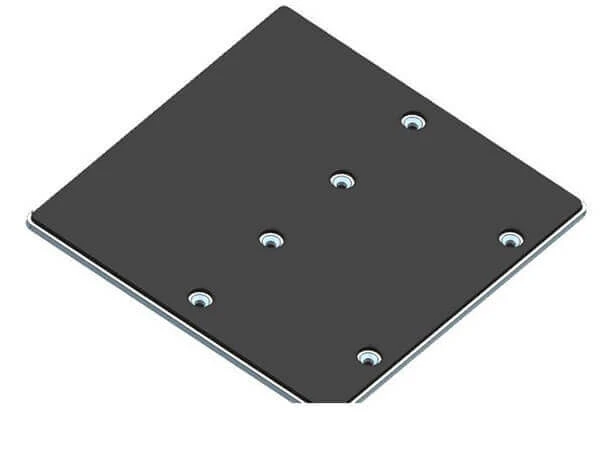

Rubber coating is one of the most widely used processes of coating in various applications. Such protective coating is applied onto or impregnated into a substrate or an object for protective, decorative or functional purposes.

Types of Rubber Used in Rubber Coating:

The following types of rubbers are frequently used for the purpose of rubber coating

- Silicone Rubber (SiR)

- Neoprene

- Ethylene Propylene Diene Monomer (EPM, EPDM)

- Natural Rubber

- Viton

- Butyl Rubber (IIR)

- Hypalons

Advantages of Rubber Coating:

- It is flexible.

- It won’t crack, chip or become brittle.

- Coating insulates from electrical shock, vibration, heat.

- Coating nullifies sound.

- It provides safe, non-slip comfort and control.

- It is durable.

- Rubber coating resists weather, chemicals, impact and abrasion.

- Improved lubricity which means lower coefficient of friction.

- Reduces stickiness.

- Rubber coating gives protection from oils, dirt and contamination.

- It has excellent dielectric strength.

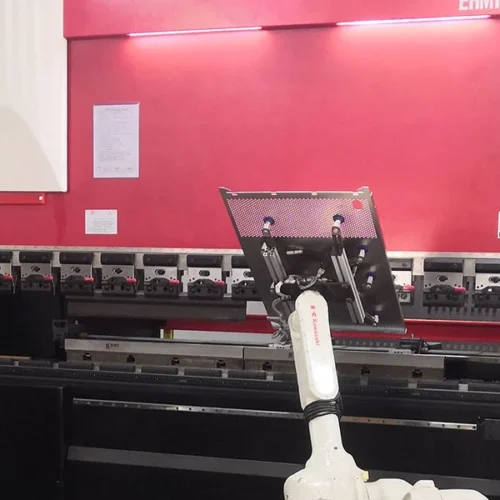

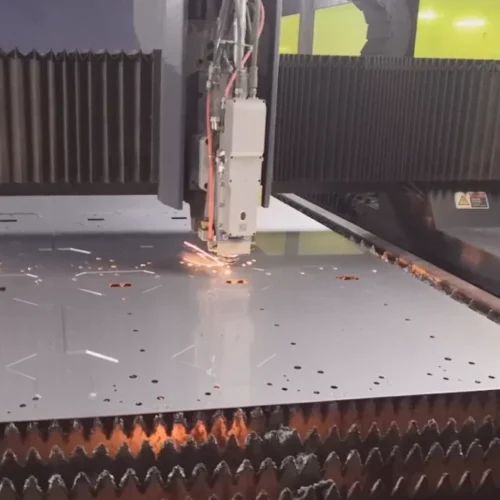

In a nutshell,with the development of Shengen company, the company has added rubber coating services to the original sheet metal processing services to meet more requirements from customers.