Custom sheet metal fabrication is vital for manufacturing with a huge list of methods and usable metals. In addition, metal is essential in how people operate in every household and working area.

Metal is a stabilizing component that makes all of today’s conveniences possible, from light fixtures and appliances.

Despite its popularity, it is vital to understand how this steel metal manufacturing process works. Here is a complete breakdown of this sheet metal custom fabrication method and its applications across various industries.

What is Custom Sheet Metal Fabrication?

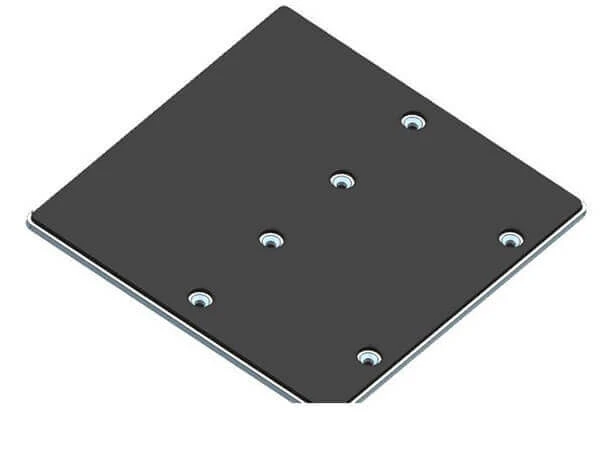

Custom sheet metal fabrication forms a flat metal sheet into the parts. You can fabricate sheets of metal using high-level machinery to form, bend, cut, and sheet metal assemblies into any shape you want.

Many metal materials are suitable for sheet metal custom fabrication, such as steel, aluminum, stainless steel, copper, and zinc.

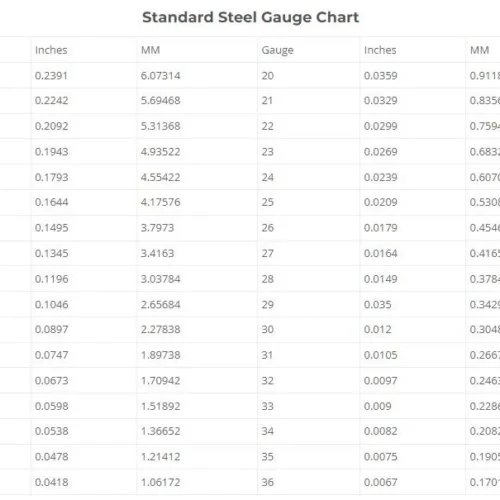

The gauges of the custom sheet metal range from about 0.006 to 0.25 inches. For heavy-duty applications, thicker gauges are best, while thinner gauges have advantages in terms of malleability.

Steps Involved in Custom Sheet Metal Fabrication

The steps involved in sheet metal custom fabrication are below:

- Designing & Drawing:

Making a design for the final product is the first step in the manufacture of custom sheet metal. Engineers are the ones who produce the design.

Modern engineers typically utilize CAD (computer-aided design) software, such as AutoCAD or Solidworks, while some fabricators still use hand-drawn designs, which can be adequate for simple jobs.

Pro-production testing guarantees the quality of the final product and gives the client a chance to test it in actual use.

- Metal Fabrication:

This is the actual method of fabricating metal, in which raw materials go through many different processes to produce the finished product. This product is manufacture through the design guidelines and budget.

- Assembly:

The last step in the custom sheet metal fabrication process is the sheet metal assemblies of all components in the components step assembly.

After the metal has been shaped or cut to fit an application, it may need to be fused or joined together with adhesives, welding, brazing, or riveting.

- Product Finishing:

The final product is sent to the finishing process after the sheet metal parts have been assembled. The features and components go through finishing techniques to improve the final product.

Depending on the final product, the components may also be brushed, polished, or shined. After that, safety mechanisms, decals, and other finishing touches are applied.

- Shipping:

The last step of the steel metal manufacturing process. The final product is packing and sent to the client or whoever will use it.

When designing packages, an essential step in the engineering process, consideration should be given to the entire logistics cycle as well as the requirements for shipping.

Steps of Custom Sheet Metal Fabrication Processes

Sheet metal can be shaped and manipulated using a variety of methods. Certain applications are better suited to some of these processes than others.

1. Custom Sheet Metal Fabrication Cutting Process:

Sheet fabrication uses rolled metal sheets. These sheets are flat and rectangular. Therefore, custom sheet metal cutting is the first step in any sheet fabrication. This procedure uses a solid force to cut or remove a metal sheet.

They are cut into two pieces without shear: Plasma cutting, waterjet cutting, laser beam cutting, and shear cutting: punching, shearing, and blanking. We will explain each technique in detail in this section.

-

Cutting with Shear:

The techniques used in cutting with shear are the following below:

-

Shearing:

Shearing works well for large-scale projects and cutting soft materials like mild steel, brass, and aluminum that don’t need clean finishes.

It makes straight lines on sheet metal with a flat surface. The cutting point splits the flat metal material. We applied a shear force to the surface in the shearing method.

-

Punching:

Shear force is also used when punching to make holes in sheet metal. However, in this instance, the scrap material taken out of the hole is the final component, while the material left on the die is the scrap material.

It can make various sizes and shapes of cutouts and holes with the help of punching. This method is quicker than blanking, resulting in clean and precise parts in a short amount of time.

-

Blanking:

Blanking is a cost-effective method for making sheet metal. Using a blanking punch and die, a small amount of sheet metal is cut out of a more extensive stock material.

During the process, the die holds the sheet metal while the punch exerts a “blanking force” on it.

-

Cutting without Shear:

Many processes enable custom sheet metal cutting without shear force.

-

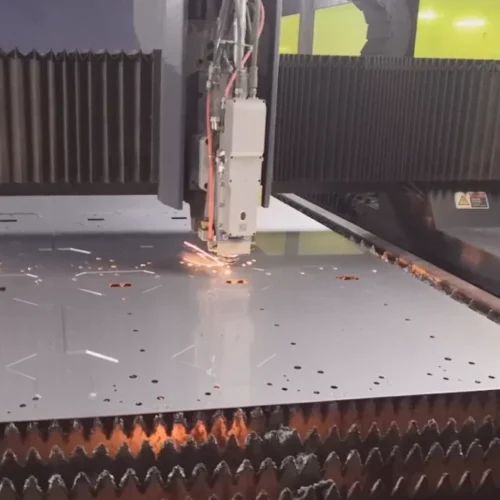

Laser Beam Cutting:

Laser-cutting sheet metal involves melting in specific locations with focused laser beams.

Laser cutters are compatible with many metals, including mild steel and non-ferrous metals. This method is comprised of two concurrently running sub-processes.

Concentrating a powerful laser beam on the sheet metal is the first method. Then, the material vaporizes from absorbing the laser beam’s thermal energy.

-

Plasma Cutting:

Plasma is used in this thermal cutting process to cut metal. The metal is subjected to a lot of heat and gradually melts away.

The cut is rough, with many burrs and an oxidized area around the cut. As a result, it is one of the best techniques for cutting medium-thick custom aluminum sheet conductive metal materials.

-

Waterjet Cutting:

A high-pressure water stream is used in this cutting procedure to cut metal sheets. Waterjet cutting is flexible and can cut a large range of hard and soft materials.

It cuts well through rubber, fabrics, soft materials, metal foils, and other materials.

2. Sheet Metal Custom Forming Process

The process for forming sheet metal reshaping materials while preserving the solid states.

However, the applications of these methods for custom sheet metal fabrication are distinct

. This section will discuss the fundamental forming methods utilized in sheet metal engineering.

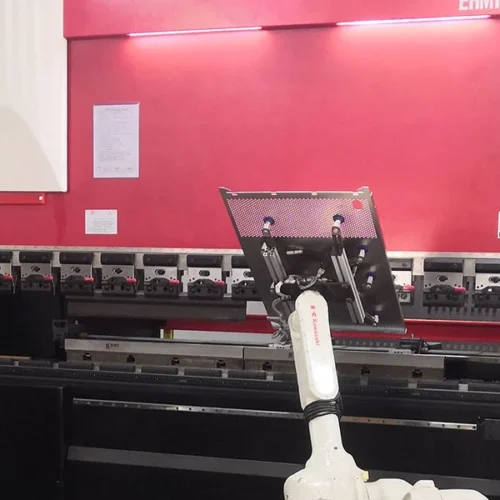

2.1 Bending:

Custom sheet metal bending offers excellent value for money when produced on a small to medium scale. It involves using force to deform the metal’s surface and bend it at the right angle to get your desired shape.

This operation can be finalized with the help of rolling machines and press brakes: Spring steel, copper, and aluminum 5052 used this method.

2.2 Hemming:

Hemming is a custom sheet metal method in which a sheet metal edge is rolling over to form a two-layered area. There are typically two stages to it.

The first step is to blend the sheet metal before lowering it into a V-die. On the other hand, in stage two, the material was isolated and put in a flattening die.

2.3 Rolling:

A metal piece is rolled by passing it through a pair of rollers to reduce or achieve a balanced thickness gradually.

To generate compressive forces, these rollers continuously rotate at a high-efficiency rate.

2.4 Stamping:

Sheet metal stamping is a cold-forming process that uses stamping presses and dies to shape raw materials.

This method works well with sheet metals made of stainless steel, low-carbon steel, high-carbon steel, aluminum, brass, copper, and other metals.

3. Sheet Metal Custom Fabrication Joining Process

The following are sheet metal custom joining techniques involved in the metal fabrication process:

3.1 Welding:

Welding combines two pieces of metal into a one-piece through heat and pressure. The face metal melts using high heat, and typically filter material is added.

Welding can be done in a variety of ways and with a variety of tools. For example, heat is applied to the points where the two pieces are frequently used to create a weld.

3.2 Riveting:

The process of riveting entails first drilling a hole in the metal sheets that will be joined and then putting in the rivet.

Next, you squash the rivet’s tail to deform it after inserting it. The rivet’s tail will be flattened, preventing it from falling off. Additionally, non-ferrous metals like copper and aluminum can be riveted.

Why is Custom Sheet Metal Fabrication Important?

In contrast to other forms of manufacturing, custom sheet metal fabrication depends on accurate measurements, layouts, and plans to produce the final product.

It is use in numerous industries like automotive, aerospace, construction, and medical, and metal custom fabrication is very important.

Many products can use for sheet metal custom fabrication, such as plastic, carbon steel, brass, and many others.

Without manufacturing, we wouldn’t have the option to utilize electrical frameworks or make things for our kitchens, restrooms, organizations, homes, and vehicles, and that’s only the tip of the iceberg.

Since these manufactured items can be producing quickly and effectively by industry, it is challenging to imagine a modern society without them.

Design Tips for Custom Sheet Metal Fabrication

Here are design tips for sheet metal custom fabrication.

1. Wall Thickness:

Each component must have the same density because sheet metal custom fabrication parts are manufactured from a single sheet of metal.

Generally, you can sheet metal manufacture parts with a thickness of at least 0. 9 mm to 20 mm. However, different methods of sheet metal custom fabrication work with different densities.

Sheet metal bending, on the other hand, can work with metal sheets with thicknesses ranging from 0.5 mm to 6 mm.

2. Holes and Slot Orientation:

When modeling parts for custom sheet metal fabrication, one must consider the diameter of holes and slots.

Additionally, there should be sufficient space between the holes. Opening dispersing should be twice the sheet metal thickness during bending or forming; closing gaps can result in breakage or deformation.

3. Bend Allowance:

The additional material length that must be added to the real parts is known as the bend allowance.

Measurements to create a flat pattern. First, however, we must remove the bend deduction from the flange size to achieve a balanced design.

Advantages and Disadvantages of Custom Sheet Metal Fabrication

Sheet metal custom comprises many methods to help create components for many industries. Therefore, the pros and cons depend on the process that you can choose.

The advantages and disadvantages of custom sheet metal fabrication are below:

Advantages of Custom Sheet Metal Fabrication:

- Efficiency and accuracy

- Easy to transport.

- Sheet metal is very lightweight.

- Wide variety of materials and finishing options.

- Numerous shapes can form with custom sheet metal. In addition, it makes a very durable surface.

Disadvantages of Custom Sheet Metal Fabrication:

- Complex bending operations.

- Minimal design

- Some applications don’t require metals.

- Sheet metal custom fabrication requires a high cost for tools and equipment.

Conclusion

In this article, we discussed the Custom Sheet Metal Fabrication processes. So, a sheet metal manufactured application is a good choice.

It is essential to comprehend the various processes involved in sheet metal fabrication and the fundamental design guidelines, materials, and finishes. Each of these components significantly increases the potential of your project.

We hope the information in this article will guide you to make a good decision.