3D Printing with metal can be difficult and expensive. Traditional metal fabrication processes are time-consuming, require specialized equipment, and are often cost-prohibitive.

Can 3D Printers Print Metal? Yes! With the latest 3D printing technology, it is now possible to produce 3D objects with metal materials. In addition, it allows for faster prototyping and production of complex parts at a fraction of the cost.

Are you looking for a qualified sheet metal fabrication subcontractor? If it’s Yes, Shengen will be your top choice!

Introduction

3D metal printing is a popular technology found in workbenches, design studios, schools, community centers, and even homes.

While most of us think of 3D Printing in terms of plastics. Actually 3D metal printing is an additive manufacturing process that uses metal to create objects.

A wide variety of applications can use this process. These include- medical devices,

selective laser melting (SLM),

aerospace parts,

electron beam melting (EBM),

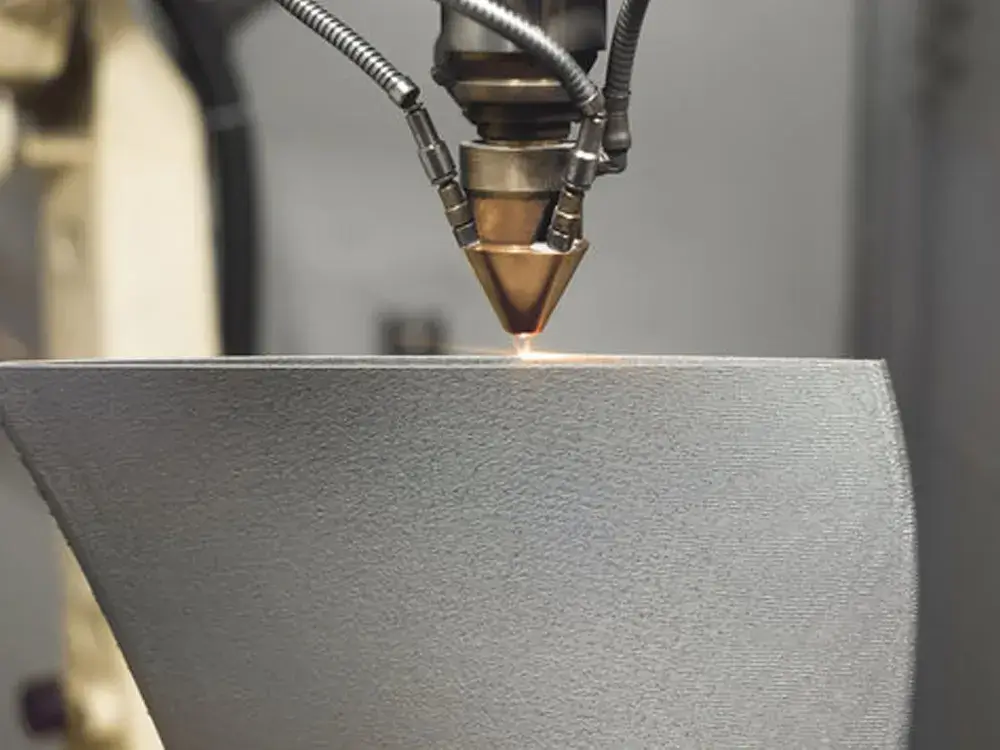

direct energy deposition,

binder jetting.

These are among the most common metal 3D printing technologies.

Each 3D metal printing method has advantages and disadvantages, so choosing the proper plan for your project is essential.

Powder bed fusion and binder jetting are popular 3D metal printing processes for rapid prototyping and finished production parts.

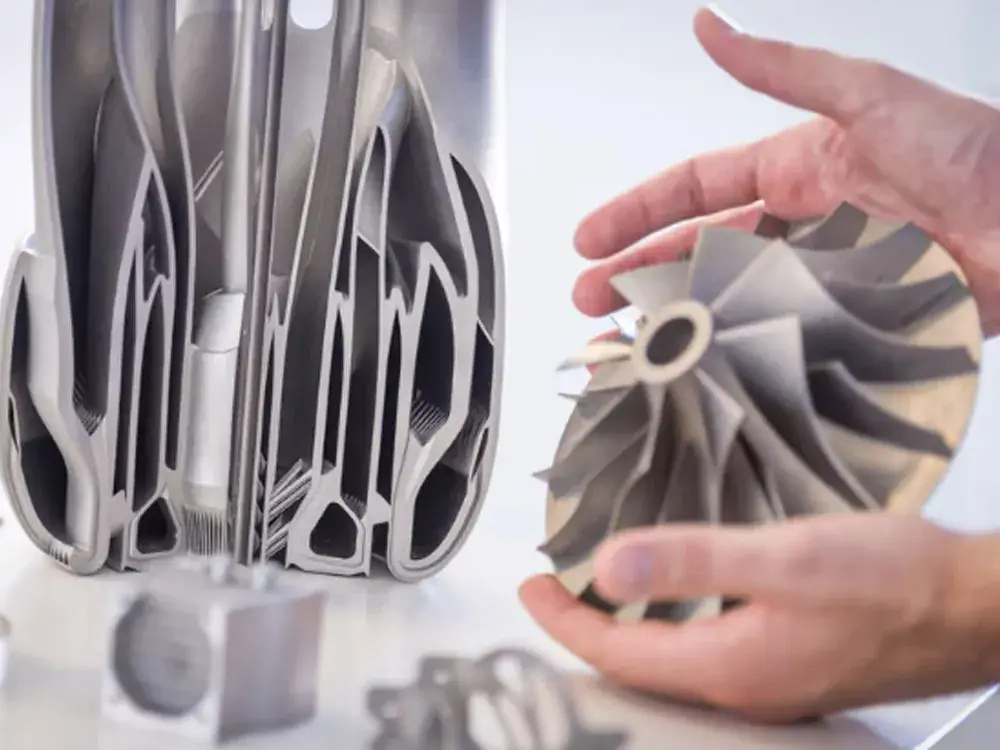

1. One of the main benefits of 3D metal printing is its exceptional design flexibility.

2. It can create geometries that are impossible to manufacture with traditional manufacturing processes.

3. That makes it possible to design organic, topology-optimized structures that can significantly improve a part’s performance.

4. Another advantage of 3D metal printing is its ability to make lightweight components.

5. It can help aerospace companies save money. It can improve efficiency by reducing the number of parts required for different tasks.

6. It also helps reduce maintenance costs and repair times, making it especially useful for producing spare parts.

For example, Boeing could save $3 million per airplane by 3D metal printing for titanium parts.

Before you start 3D metal printing your parts, you should know a few essential things. First, it is crucial to design your piece to maximize its stiffness and minimize its mass. To do this, you should experiment with the orientation of your part and make sure to include self-supporting features.

What Is 3D Metal Printing?

3D metal printing is a process that uses computer-controlled additive manufacturing techniques to build metal parts. It’s a cost-effective way to produce complex metal parts with high accuracy and is suitable for prototypes and production runs.

Medical professionals use 3D metal printing to create customized, patient-specific medical devices. Such as orthopedic implants, which offer increased functionality and durability. One can also use this process to manufacture parts for aerospace applications.

The most popular metal 3D metal printing processes are Directed Metal Laser Sintering (DMLS) and SLM. Various metals and metal alloys can be used with these processes to produce parts with excellent physical properties and good surface finishes.

Both DMLS and SLM are forms of 3D metal printing. They can be used with an extensive selection of metals, such as aluminum, stainless steel, and titanium. Other common materials include cobalt chrome and Inconel.

Manufacturers often use refractory metals and alloys, such as bronze, to make components that resist extreme temperatures or corrode in harsh environments when they print other metals.

Another common 3D metal printing technique is binder jetting, which builds parts layer by layer. First, a binding agent is sprayed onto a thin powder coating through inkjet nozzles to deposit it. Because it doesn’t require support structures, binder jetting is a cost-effective option for small production runs.

What Materials Can Be 3D Printed?

3D Printing is a technology that uses materials that can be melted or turned into a powder, then hardened to form a solid. Manufacturers can use 3D printing metal parts to produce objects. Typically, those objects cannot be made using traditional methods, such as medical appliances.

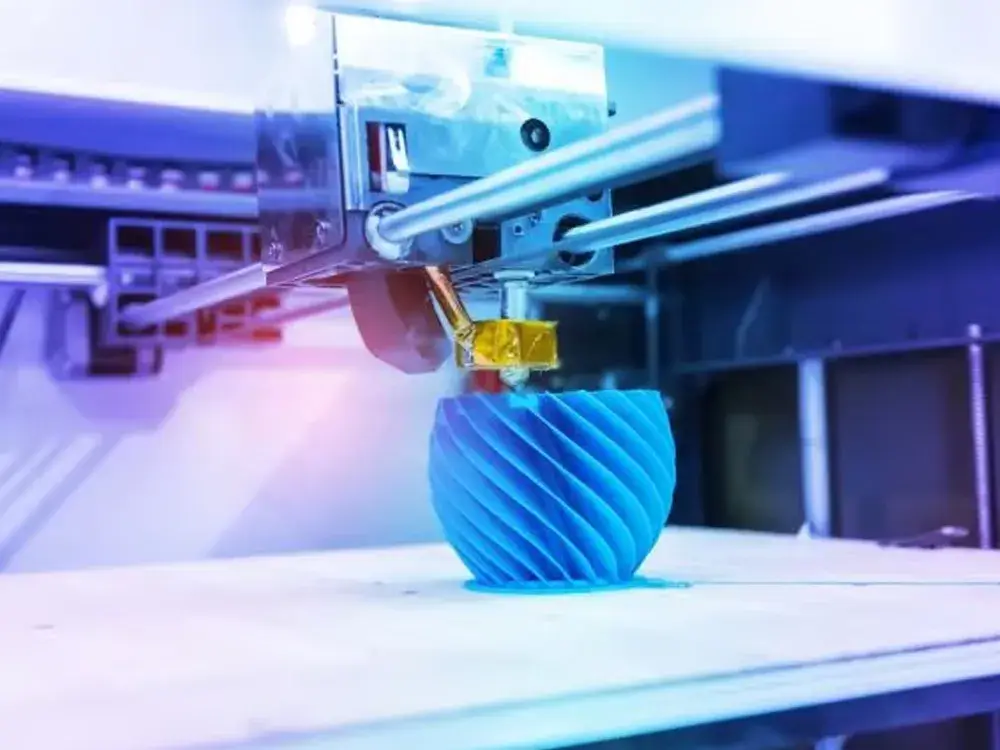

Plastic is the most common 3D printing material, with many colors available. Its firmness, flexibility, and smoothness make it popular with consumers and creators alike.

Plant-based resin is another popular 3D printing material that’s biodegradable and eco-friendly. In addition, it is compatible with SLA printers and produces durable builds.

A 3D printer can print metals, resins, and other materials in addition to plastics. For example, exposure to UV light can shape resin, a liquid polymer, into a finished product. Here is a small list of what metals can be 3d printed:

- Carbon Fiber: As a top coat over plastic, composites such as carbon fiber can increase the strength of plastic materials and improve their durability. Other reinforcement materials include graphene, fiberglass, and Kevlar.

- Titanium: As a strong, lightweight, and heat-resistant metal, titanium is an excellent choice for many 3D prints. FDM or direct metal laser sintering (DMLS) technologies can produce it.

- Aluminum: Manufacturers often use this to create complex and intricate models. It’s also a reliable choice for prototyping and production, with its solid and flexible properties. In addition, you can 3d print aluminum with ease.

- Stainless Steel: It is also a favorite for manufacturing products with strength and durability. People can use it to make everything from the hulls of boats to the wing flaps of aircraft.

Several reasons a company may want to invest in metal 3D printers. They can help reduce costs, increase productivity, and speed up iteration cycles.

Costs can vary widely depending on the machine, the material used, and the complicated design.

When producing components with 3D metal printers, the fabrication process is taken into account. The duration of the production is also taken into account.

For example, a metal 3D printer using Fused Deposition Modelling (FDM) requires high-quality powdered materials. Unfortunately, these are much more expensive than non-powdered metals, and one must prepare the powder before use.

Another type of metal 3D printing technology uses filament extrusion. It is more simple to operate and less dangerous than powdered metals. However, it does require additional post-processing steps, including de-binding and sintering.

These processes can be very time-consuming, and it’s easy to see how the overall production time can be pretty significant. Therefore, it is essential to factor this into your decision-making when deciding whether to invest in a metal 3D printer.

Are You Looking for A 3D Metal Printing Supplier?

3D Printing has become a popular process for many businesses and individuals. People can use it to build houses, create toys, and even 3D print food! However, not everyone knows that you can also 3D print metal.

A widely used 3D printing technology is Direct Metal Laser Sintering (DMLS). This process uses powder to build up parts layer by layer.

Engineers can use this process to build various metals and alloys, including stainless steel, cobalt chrome, aluminum, nickel alloy, and titanium. In addition, this process provides an excellent solution for prototyping or low-volume production.

Another option is Selective Laser Melting (SLM). This process works by melting a powder until it forms a solid metal. Users can use it to produce prototypes and end-use parts for one-off production, parts replacement, or low-volume production.

When choosing a 3D printer, you should look for a company that offers various methods to build your parts. The most common process is laser-based, but other functions use binders or liquids to form the pieces.

ShengenMFG offers a wide selection of materials. We use high-quality printers and provide thorough quality inspections of their products. We also have rigorous standards for our CAD files and suggest improvements during the design phase.

Conclusion: Can 3D Printers Print Metal?

People are using 3D printers for everything. And their popularity is increasing daily. Every industry uses them, ranging from aerospace and automotive to engineering and astronomy.

For the best use of this technology, it is essential to choose a service provider with depth and breadth of experience. You should also check out their 3D printing solutions suite. It should include state-of-the-art machinery for metals such as titanium and stainless steel.

They should also have a quality assurance team that can help you avoid the pitfalls of manufacturing by hand. They should offer advice on materials, tools, and processes to get the most out of your investment.

So to answer your question, can you 3d print metal? We say YES! In the end, 3D printing metal materials is a great way to create parts and assemblies. It is without the cost and downtime of traditional manufacturing methods. The process has the potential to revolutionize the industrial and commercial sectors.

It can also enable the manufacture of highly functional components ideally suited for their intended use. An excellent example is robotic arms that can produce highly engineered, precision-fitted prosthetics.

While there are many 3D Printing methods, the most common ones are:

- Selective Laser Melting (SLM)

- Direct Energy Deposition (DED)

- Electron Beam Melting (EBM)

- Binder Jetting

ShengenMFG offers the latest additive manufacturing to suit every need, from small to large.