Tool and die is a unique field in the manufacturing industry. It entails creating gauges, cutting tools, dies, fixtures, jigs, and other related tools that can be used in the manufacturing industry. Tool and Die are often used interchangeably to mean the same thing. Although, there are some little functional differences between the two terms. However, many engineers who deal with tool fabrication also engage with dies. To know what tool and die are, highlighting their differences will help distinguish one from the other.

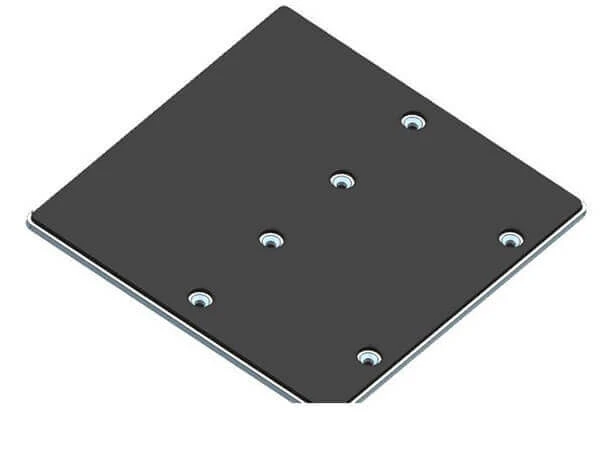

Dies are a subset of tools, and all dies are categorized as tools. They are those tools that functionally change the shape of metals, and they are the female component of larger tools. As all dies are regarded as tools, tools cannot be regarded as dies. On the other hand, a tool is any mechanical device used in cutting, forming, supporting, and molding metals in line with stamping. As a result, jigs and fixtures, drills, and cutting blades are categorized as tools. In tool and die making, the punch block is seen as die, but the structural components involved, like the fixtures, remain tools.

To better understand the tool and die, dies should be looked at from their functional classification. Dies are known to function in cutting or forming stock material. For a die to be taken as a cutting die, it must be able to cut, removes, or shear materials. When a die cannot remove anything, such is seen as forming a die. However, some die also combine cutting and forming in commercial tools and die.

Types of Die

Dies can be categorized based on their function and the strokes of the press as a portion of the entire tooling process.

- Simple Die: it can only perform a single cutting and forming action per stroke. The simple die machine is cost-effective and also less efficient, where multiple tasks need to be performed.

- Compound die: with this, a single stroke can fulfill multiple cutting and forming actions.

- Progressive Die: it has one of the most efficient methods that help in accomplishing multiple operations at a go than bit by bit. With a single stroke, multiple cutting and forming are performed.

- Transfer Dies: this starts with pre-cut blanks meant to be transferred mechanically between stations. With transferring of the Die, the efficiency of work can be heightened, and work with more prominent and complex parts.

- Multiple Dies: this Die is unique as it creates multiple components with each press stroke. For identical dies to work together, they are synchronized to the exact control mechanism.

Tool and Die Making

The art involved in tool and die making is close. Industrial art handles the manufacturing of stamp dies, plastic molds, jigs, and fixtures used to produce solid waste in mass.

- Tool Making

Tool-making deals with the creation of tools that are used in the production of goods. The typical tool-making in the manufacturing industry includes fixtures and cutting tools. It also involves machine tools used in testing, holding, or manufacturing goods while fabricating is due to the specialized work of tool makers, fabricating of custom tools is frequently needed in improving the standard of tools.

- Die Making

Die making is a subdivision of the tool-making process and concentrates on the maintenance and creation of dies. It involves making the set of dies, and dies and punches, steel rule dies. In die steels and punches, accuracy is needed to create the components involved.

Importance of tool and die process in metal works

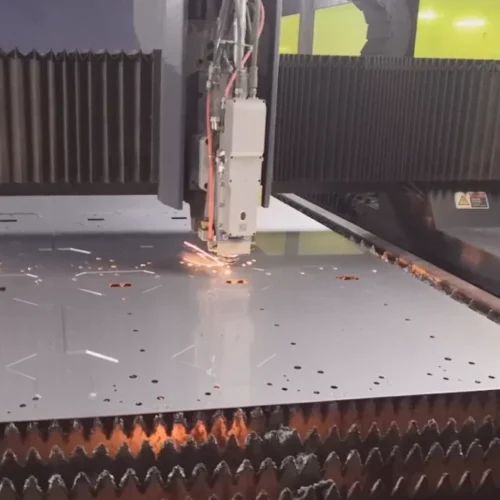

Broadly, tool and die involve making different parts of metals in a more specialized way. The process of making various metal parts requires using some custom tools and dies for cutting and shaping the metal into the required shape to be used. Design is the fundamental aspect that is involved in the tools and dies process because it is the design that is sent to the computer for simulation and allows for accuracy in the manufacturing process.

- Creation of specialized tool: in all metal works, tooling is essential in completing all the works. And tooling is made up of tools and dies used in cutting and shaping metals. For the part that will be manufactured, there is a custom design of tools with precision for a desirable outcome. With the tools and dies, the tooling will be designed to cut and shape the metal to meet its purpose.

- For engineering design and specialized metal stamping: in design engineering, custom metal parts are designed and created. And in creating a custom metal part, design engineering comes to play, requiring precision and accuracy to get it done. In the tools and dies process, specialized custom stamping is essential as the first process involved in custom metal parts is tool and die. With metal stamping through the tools and dies process, a wide range of applications can be created. Therefore, in the manufacturing industry, tool and die is crucial in creating molds, machine tools, cutting tools, dies, and other valuable tools.

- Welding and finishing: welding involves joining two or more pieces of metal. While finishing deals with polishing or cleaning metal parts. Tools and dies the two aspects are vital to process in the manufacturing industry as it gives precision and accuracy to the metal work created for a wide range of use.

Tool and Die marker and their responsibilities

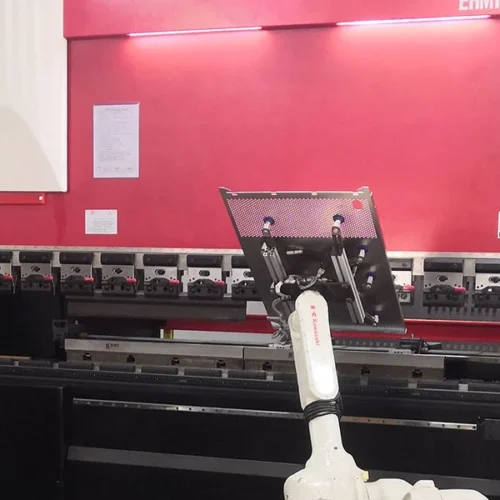

A tool and die maker is a person who involves himself in setting up and operating varieties of computer-controlled or mechanically controlled machine tools. From his operation, he produces precision tools and dies metal parts and instruments.

What tool and die markers do

Those involved in tool and die study blueprints, sketches, specifications, or computer-aided designs. They also handle computer manufacturing files that make tools and dies.

- Tool and die markers see to the computing and verification of dimensions, sizes, shapes, and workpieces tolerance.

- They are responsible for setting up, operating, and tearing down conventional manual and machine tools based on numerically controlled computers.

- The proper fitting together of parts is also one of the duties of tool and die makers through filing, grinding, and adjusting.

- They see the final testing of tools and dies to meet the specifications.

- Inspections for dimensions and defects are done by tool and die makers to ensure that everything is in a suitable condition.

Aside from the duties mentioned above of tools and dies experts, other tasks they also perform in the manufacturing industry center on the crafting of precision tools and their holders, which are used for cutting, shaping, and forming metals and other materials. Their function also extends to the production of jigs and fixtures devices that hold metals.

Things to know before going into the tool and die making

Tools and dies making is a skilled field in the tool and die manufacturing companies. It involves technical know-how both with the digital tool and die and machine. There are some things you should know to get started in this field

- Know the job description and responsibilities: Before entering this industry, you should be conversant with what tool and die makers do to prepare for the task ahead. Some of their job descriptions are repairing and building custom machines with machine equipment and measuring instruments. They also create or modify tools, dies, jigs, prototypes, and fixtures from scratch or prototype. Among other things, they calculate the dimension and tolerance for setting up machines. In line with their job descriptions, there is also an array of responsibilities that their work involves, as mentioned above.

- Get familiar with valuable tips to become a tool and die maker: to be a tool and die maker, you must have a good knowledge of the molding skills involved in the tool and die company. With this skill, you can create, design and shape different metals for various purposes.

- Poise yourself for the necessary skills: you need many skills to succeed in this field to be a professional and commercial tool and die maker. Some of the skills you need to have in jig and fixture making are using assortment machines in building devices in the industry. Welding knowledge is also needed for tool welding and heat treatment of steel tools. Also, a good understanding of mathematics and computer is necessary to work with CAD/CAM technology and computerized machines.

Things to know before going into the tool and die making

Tool and die making is a skilled field in the tool and die manufacturing companies, and it involves technical know-how both with the digital tool and die and machine. There are some things you should know to get started in this field

- Know the job description and responsibilities: Before entering this industry, you should be conversant with what tool and die makers do to prepare for the task ahead. Some of their job descriptions are repairing and building custom machines with machine equipment and measuring instruments. They also create or modify tools, dies, jigs, prototypes, and fixtures from scratch or prototype. Among other things, they calculate the dimension and tolerance for setting up machines. In line with their job descriptions, there is also an array of responsibilities that their work involves, as mentioned above.

- Get familiar with valuable tips to become a tool and die maker: to be a tool and die maker, you must have a good knowledge of the molding skills involved in the tool and die company. With this skill, you can create, design and shape different metals for various purposes.

- Poise yourself for the necessary skills: you need many skills to succeed in this field to be a professional and commercial tool and die maker. Some of the skills you need to have in jig and fixture making are using assortment machines in building devices in the industry. Welding knowledge is also needed for tool welding and heat treatment of steel tools. Also, a good understanding of mathematics and computer is necessary to work with CAD/CAM technology and computerized machines.