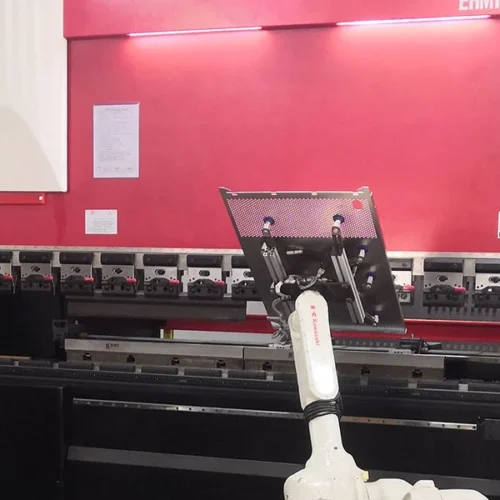

In order to further develop the company and meet the higher level requirements of customers, Shengen has introduced foreign automatic bending machines to improve the accuracy of bending.

Robot-Bending workplace and its components:

Workplace is a single unit of a production system that is organized based on machine tool (or group of machine tools) serviced by a robot (operator) and additional servicing equipment if needed. Workplaces are integrated into the production system. This production system belongs to a company, which could be a part of an industrial network or cluster. The workplace integration with systems and processes could happen through the material flows and information flows.

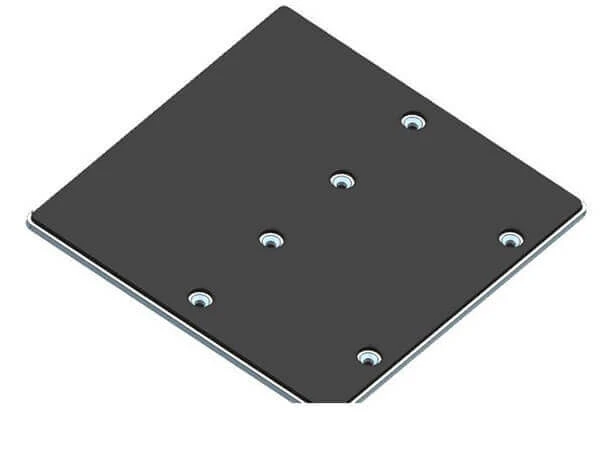

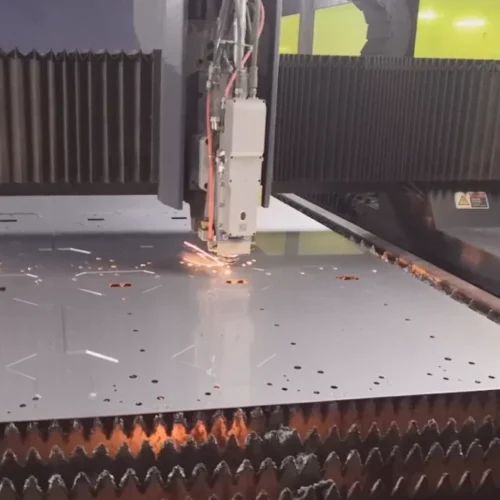

Numerically controlled sheet metal flexible bending cell with the robot as the core execution part is a set of highly automated equipment combination which has the advantage of high efficiency, high quality and high flexibility. The bending accuracy depends on the press brake machine (bending machine), positioning accuracy of the robot and the coordinated control of the robot and the press brake machine. The difficulty of collaborative control lies in the speed matching between the robot and the press brake machine, and the robot supporting the moving trajectory of the workpiece.

A robot bending cell can efficiently complete one job after another.This makes production more profitable, even for smaller orders. For exceptionally heavy or complex parts, even a single piece can be automatically produced in an economic way.