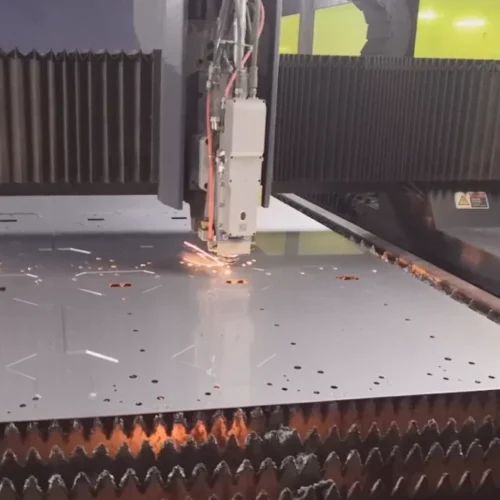

In order to improve the accuracy and work efficiency of welding technology, Shengen introduced a robot welding machine to meet the needs of the company’s development and customers.

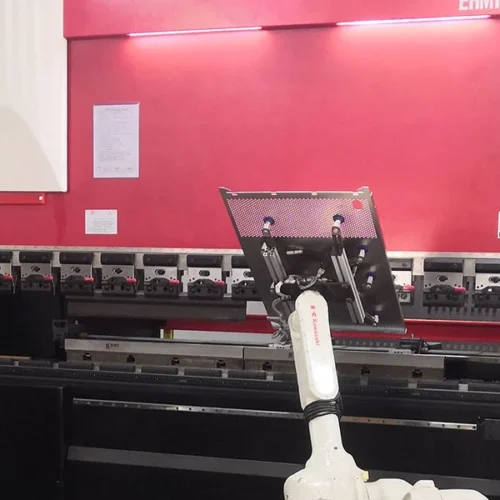

Bringing in a welding robot requires changes that are supposed to accommodate automation. Welding robots use a variety of tools that are not a part of manual equipment. Tectilinear types of welding robots are able to move their arms in three dimensions while articulating can move in more planes.

A wire feeder will send the filler wire to the robot while a high-heat torch at the end of the arm melts the metal. The combination of the two is usually what robotic welding processes are comprised of. The temperature can get very high, so using a robot instead of a human increases safety.

Shengen trains professional welders to operate this machine, in order to maximize the value of this machine, and at the same time can improve the accuracy of welding.