What is sheet metal fabrication?

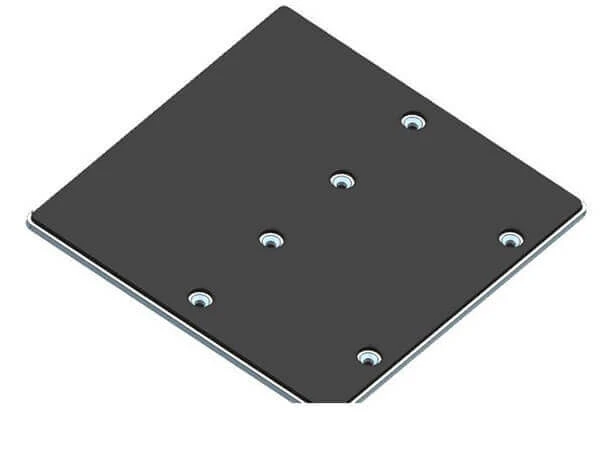

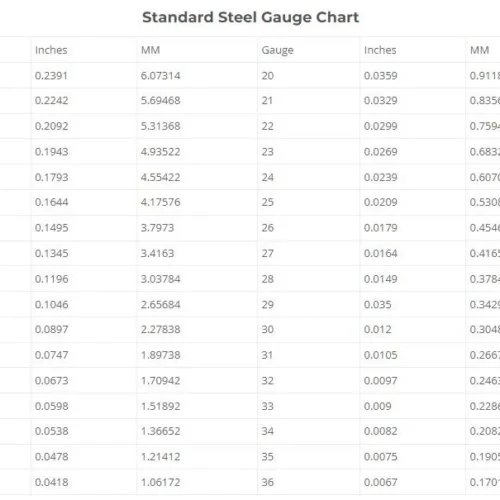

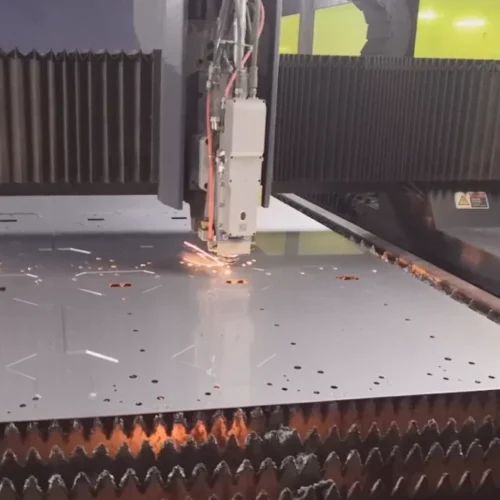

Sheet metal fabrication is a technique that starts with raw sheet metal. Under some sheet metal fabrication methods, like cutting, punching, folding weld, riveting, splicing, forming, etc., to get fine sheet metal fabrication parts or other products. The biggest difference between sheet metal fabrication and metal fabrication is the thickness. Sheet metal fabrication does not change the thickness, but metal fabrication changes the thickness.

Benefits of sheet metal fabrication

Sheet metal fabrication is cost-effective, which can finish mass production in a short time. It not only speeds the time of a project, but improves the quality of a project. During this kind of processing, the final products are of high quality and all meet the standards.

Under sheet metal process, you can get the desired shapes, functions, and sizes. Moreover, the final products are strong and long-lasting.

Sheet metal fabrication has countless benefits. Here are the most prominent advantages of sheet metal fabrication.

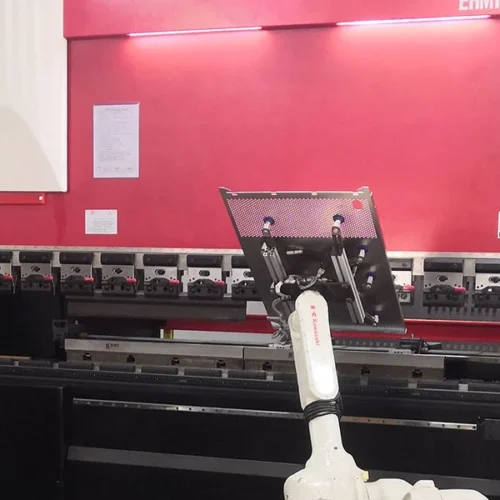

- High efficiency

- Durability

- High precision

- Aesthetics

FAQ

Q1. Why choose us?

1). We are a professional OEM sheet metal fabrication supplier

2). We provide OEM sheet metal fabrication parts

3). We have competitive prices and lead time

4). High-quality products

Q2. What do you need to provide a quote?

Kindly provide:

A. Materials B Surface Finish C. Tolerance D.Quantity

Q3. How does the payment process work?

Payment terms are flexible for us in accordance with specific conditions. Generally, we advise 50%TT deposit. Balance be paid before shipment.

Q4. How do I know about the production?

We will double-confirm your requirements and send you the sample before mass production. During the mass production, we will keep you informed of any progress. Besides, we will do a 100% quality inspection before shipment.

Q5. How can I find out about the delivery?