Sheet Metal Fabrication and Sheet Metal Assembly Services

Sheet Metal fabrication services have become an extremely vital part of the manufacturing and construction industry today.

Whether you’re looking to construct a brand-new product or retrofit an existing one, you’ll want to ensure that your product meets the highest standards of quality and safety.

To make sure your product is up to par, you should hire a qualified and skilled sheet metal fabrication service to do the job for you.

Are you looking for a qualified sheet metal fabrication subcontractor? If it’s Yes, Shengen will be your top choice!

Sheet Metal Fabrication Service Overview

What is Sheet metal fabrication? It is the process of creating and assembling various objects from thin metal sheets. The process can be applied in diverse industries. It is a cost-effective and flexible solution for large and small-scale projects.

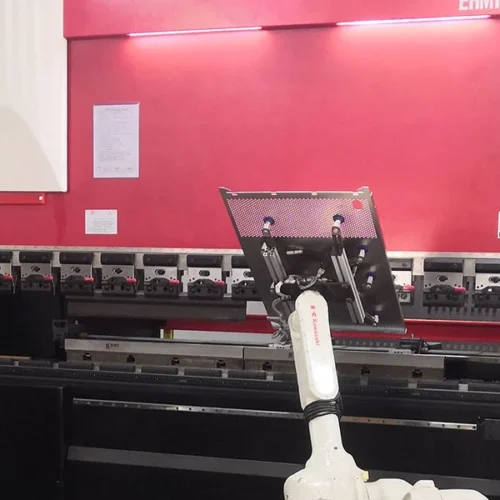

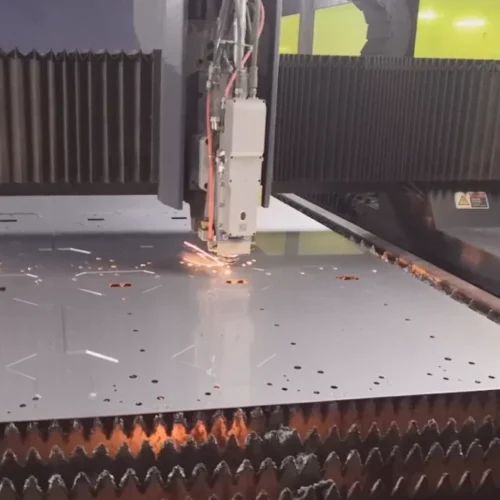

Among the different techniques used in the sheet metal fabrication service is basic and advanced cutting, bending, and finishing. These methods combine different parts into a finished product following design guidelines.

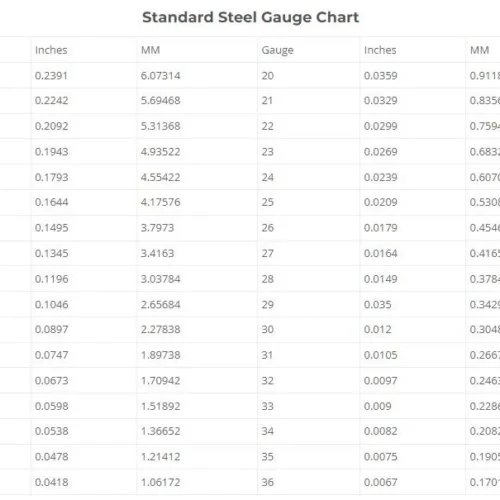

Basic cutting is the first stage in the fabrication process. For thinner materials, a fiber-optic laser can be used. For thicker gauges, a CO2 laser is required.

Another technique for cutting is shearing. Shearing is also known as blanking. This method is used mostly for non-industrial end products.

We offer a wide range of Sheet metal fabrication and Sheet metal assembly services to meet the needs of our customers. We can offer design assistance, pattern making, 3D CAD modeling, prototype development, and manufacturing, as well as complete project management.

What Is Sheet Metal Fabrication Process?

Sheet metal fabrication is a process that transforms flat pieces of metal into finished products. It’s a versatile process that can be used in a wide variety of industries, including HVAC, transportation, robotics, and construction.

- The first step involved in sheet metal fabrication is to lay out a blueprint.

- Depending on the design, a blueprint may include material selection, surface finishing, and manufacturing information.

- These documents are then rechecked to ensure that they follow specifications.

Sheet metal is available in plain, ribbed, and perforated forms. It can be made from aluminum, copper alloys, steel, and stainless steel. Some other materials include polycarbonate, nylon, and acrylic.

Sheet metal is typically produced in flat sheets between 0.5 mm and 8 mm in gauge. Thicker gauges are hot rolled. However, the exact thickness and dimensions of the material are dependent on production specifications.

What Is Sheet Metal Assembly Process?

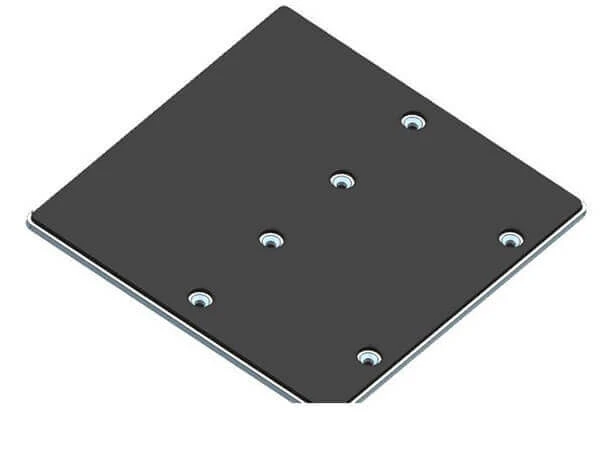

Sheet metal assembly is a process of combining and joining parts of sheet metal together. It is commonly used in automotive panels, computers, and medical devices.

The process is done with various techniques. Some of the common methods include riveting, shearing, and bending. Each of these techniques adds strength to the assembly. However, the process varies according to the materials and equipment.

Riveting is a technique that is typically used for sheet metal parts. The method has a similar effect to welding but is less permanent. This is a good option for sheet metal components that need shear strength.

Shearing is the most common method of cutting sheet metal. This involves placing the metal between two blades. The blades then force the metal to the edge. Usually, the blades are hand-held, but a machine can be used.

Sheet Metal Assembly Service

The process of sheet metal assembly involves the joining of metal parts together. Various techniques are used, depending on the type of product.

Basic sheet metal assembly uses welding and binding methods. Other procedures can be used for metal assemblies. These procedures are important to improve the quality of the product and help minimize deformation after the assembly process.

Our sheet metal assembly service provides the ability for customers to work on their projects by providing them with the necessary materials and equipment to do so. The sheet metal assembly service helps people who have an idea but don’t have the means to create it themselves.