Welding sheet metal can be complicated if you don’t have the right tools and techniques. You could end up with weak welds, or worse; you could cause damage to the sheet metal.

This in-depth guide to welding sheet metal will provide you with everything you need to get going. Then, with our help, you’ll be able to weld sheet metal like a pro!

Are you looking for a qualified sheet metal fabrication subcontractor? If it’s Yes, Shengen will be your top choice!

Introduction: How to Weld Sheet Metal?

We can use welding sheet metal for many different purposes. Sheet metal can be cut into various shapes and sizes and welded together to join. People often use it for car body panels and other structures.

When welding sheet metal, the proper technique must be used to ensure that it melds together correctly, which can be challenging, especially when working with thinner sheets.

When welding thin sheet metal, it is essential to be mindful of the heat applied to the sheet. Too much heat can cause warping and blow-through.

When welding sheet metal, it is essential to run a series of short welds in small sections rather than trying to run a single bead across the entire thickness. It will reduce the heat that must be put into it and strengthen the joint.

Both flux welding and spray welding are effective ways of joining metal components, but they have different advantages and disadvantages. Flux welding is relatively easy to learn and can be used for various metals, but it is not as strong as spray welding.

Spray welding is more expensive and requires a unique welder, but it produces a stronger, more reliable weld. Depending on the application, either flux welding or spray welding may be the better choice.

Welding Process for Sheet Metal

MIG Welding Process for Sheet Metal

Welding with gas MIG, or gas metal arc welding, is an excellent method for welding sheet metal. It combines a continuous solid wire electrode with inert shielding gas to form a weld puddle.

This welding process uses aluminum, stainless steel, and mild steel. It produces high-quality, consistent welds and is popular for many projects.

In MIG welding, the welder feeds a continuous solid wire into a weld puddle, which melts and forms a weld bead. Inert shielding gas surrounds the puddle to prevent atmospheric contamination.

When welding sheet metal, it’s best to choose a wire smaller than the metal you are welding, as this reduces the energy it takes to melt and minimizes the appearance of burnouts (melted metal puddles).

Ensure that you choose a filler metal for welding sheet metal that is compatible with the mechanical properties of the material being welded and thick enough to melt and hold together correctly.

TIG Welding Process for Sheet Metal

The TIG Welding process is an effective way to weld sheet metal and helps to avoid distortion of the material. It involves establishing an electric arc between a non-consumable electrode (tungsten) and the part to be welded, with or without filler metal.

TIG welding sheet metal requires a tungsten electrode and a shielding gas, a combination of argon and helium or pure argon gas.

Generally, a tungsten electrode with the smallest diameter is preferred to avoid burning or melting the sheet during TIG welding sheet metal. The 0.020 and 0.040-inch thoriated tungsten anodes and the 1/16 inches of created tungsten are ideal for this process.

When welding sheet metal, make sure you use a high-quality TIG torch. It is necessary to ensure the safety of the welder and the arc.

People can use TIG welding to weld sheet metal, including aluminum, steel, and stainless steel, depending on the application to weld thicker or thinner sheets.

MIG Welding Vs TIG Welding

Consider the type of material you’ll work with when deciding between TIG vs. MIG welding. For example, MIG welding is better for thicker materials, such as sheet metal and steel, while TIG welding is better suited for thin materials, such as aluminum or stainless steel.

A special aluminum welding wire is often needed for MIG welding aluminum, while you can weld sheet metal with a standard MIG welding wire.

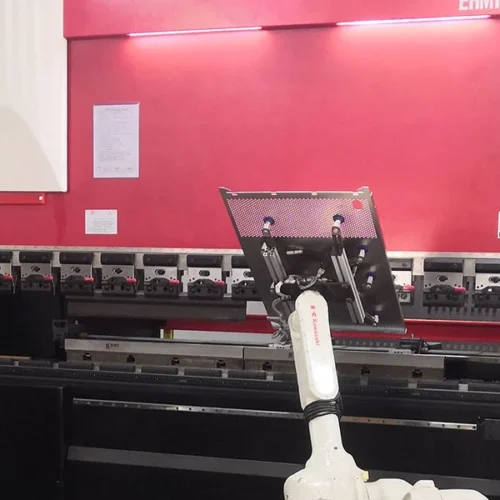

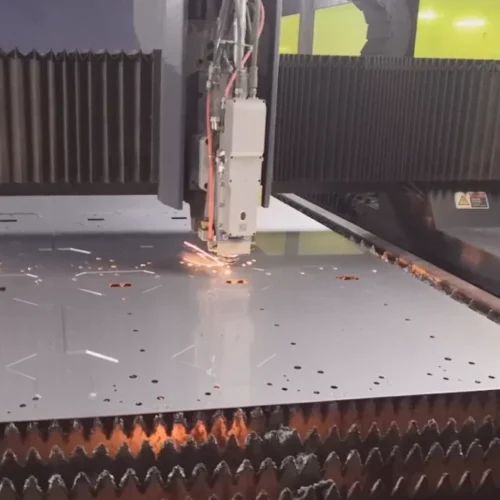

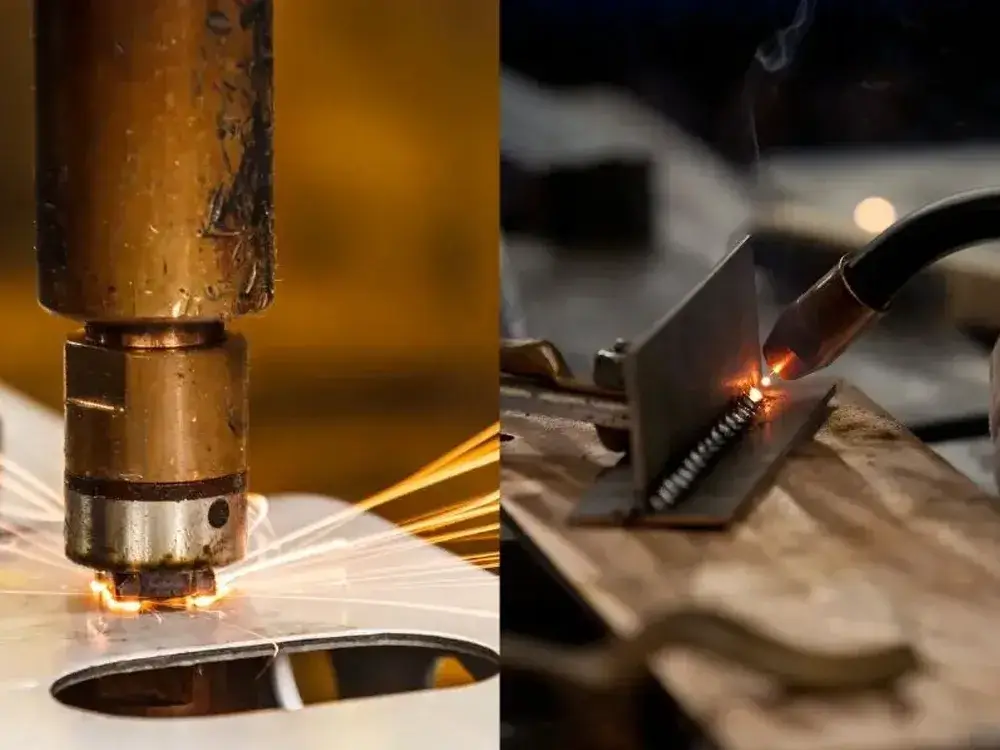

Laser Welding Process for Sheet Metal

Laser welding is an effective way to weld sheet metal. As a result, many industries, including aviation and automobile manufacturing, use it.

Its advantages over traditional welding processes include the following:

- High Speed

- Small Deformation

- Beautiful Weld Seam

During the laser welding process of welding sheet metal, the base metal is heated and vaporized, creating a narrow tunnel known as a keyhole. This tunnel allows the laser to penetrate deeply into the metal.

The depth of the welds can vary from 2 mm to 25 mm, depending on the type of metal. However, a few key factors determine how deep the welds are.

Tools for A Welder

Welding sheet metal is a highly technical process requiring many tools. In addition, you’ll need protective gear to keep yourself safe, and you’ll also need to use measurement tools to ensure that you do your work correctly.

- A metal file is an excellent tool for removing slag and burn marks from a weld.

- In addition, a wire brush can be helpful when cleaning up welds and other areas.

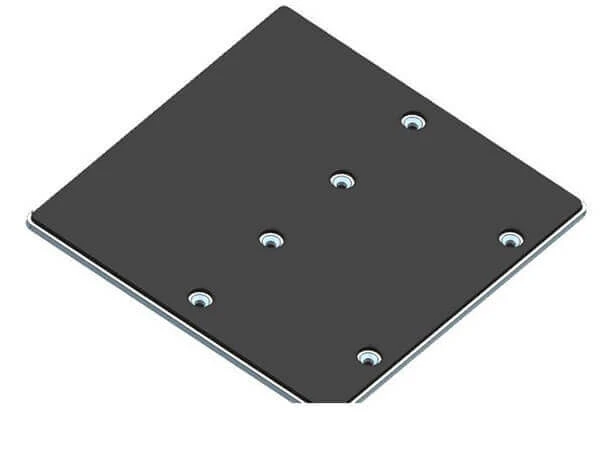

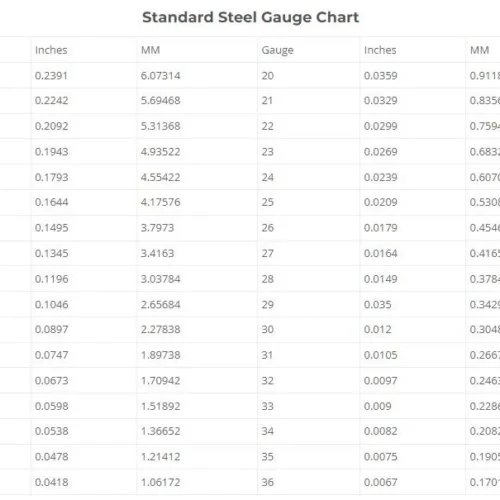

- Another essential tool is a sheet metal gauge, which helps you determine how thick the metal is.

- A scribe is another tool you’ll need to help you mark your work pieces before cutting or welding them.

- It’s a good idea to get a high-quality scribe that has a tungsten tip, which will make it last longer.

Welding Different Metals:

Welding Stainless Steel

Performing stainless steel welding can be challenging, mainly when working with thin gauge metals. In addition, unlike carbon steel, stainless steel is much more sensitive to heat input and can warp or burn through if exposed to too much energy.

Choosing the proper welding process while welding sheet metal and filler metal is critical to controlling the heat applied to the sheet metal.

It’s also essential to choose the suitable gas for your welding machine when welding the sheet metal. Typically, a tri-blend shielding gas that contains argon and helium is the best choice for MIG welding stainless steel.

We should not often use a low-carbon dioxide blend to increase the heat transfer to the workpiece, as it can cause oxidation.

Welding Aluminum

Sheet metal welding requires expertise and specialized equipment to achieve successful results when working with aluminum. The correct shielding gas is critical, as is the pre-weld and post-weld processing, both of which must be done according to specific specifications.

Welding Aluminum also poses other challenges, such as its high thermal conductivity, rapid heat transfer, and the formation of an oxide layer during welding. It is essential to consider all of these factors and use the right processes and techniques to ensure that welds are strong and reliable.

Using specialized equipment and experienced personnel will undoubtedly result in successful sheet metal welding projects with aluminum. Another challenge is porosity. It is a result of the presence of hydrogen in liquid aluminum. Once the aluminum and filler material starts solidifying, the hydrogen can no longer hold onto it. Instead, the filler absorbs the metal, producing porosity.

During aluminum welding, a welder should use a higher-than-normal percentage of argon in their shielding gas because it doesn’t react with aluminum like oxygen. In addition, it helps prevent oxidation, which can damage the weld.

Final Words

Welding sheet metal is an important skill to have when it comes to working with sheet metal. Sheet metal welding is an art form that requires precision and practice to perfect.

When welding sheet metal, you must have the right equipment and materials. It includes sheet metal, welding rods, a welding machine, and a clamp. Manufacturers use the welding machine to generate the heat needed to make the weld.

The welding rods should be the same type of metal as the sheet metal so that the two pieces will bond properly. Finally, the clamp holds the two pieces of metal together.

Once you have all the necessary materials and equipment, you can begin the welding process. Start by setting the welding machine to the correct setting and then use the welding rods to create a bead along the edge of the two metal sheets.

You will then use the welding machine to heat the bead to create the weld. The heat will cause the two pieces of metal to bond, creating a permanent connection.

After completing the weld, it’s crucial to inspect the weld to make sure it is secure. If any part of the weld is weak, you can use extra welding rods to reinforce the area. Once you have completed the inspection, you can clean up the area and remove any excess material.