What is Precision Sheet Metal Fabrication?

Precision sheet metal fabricator produces detailed and accurate sheet metal prototypes. For example, kitchens, cars, trucks, electronics, HVAC, and building constructions. All of these fields require metal components from precision sheet metal fabricating.

Precision sheet metal fabrication encompasses a wide range of manufacturing techniques. This article lists three methods of fabrication:

-

Deforming the metal workpiece into the desired geometric shape.

-

Removing material to achieve the desired result.

-

Joining semi-finished materials.

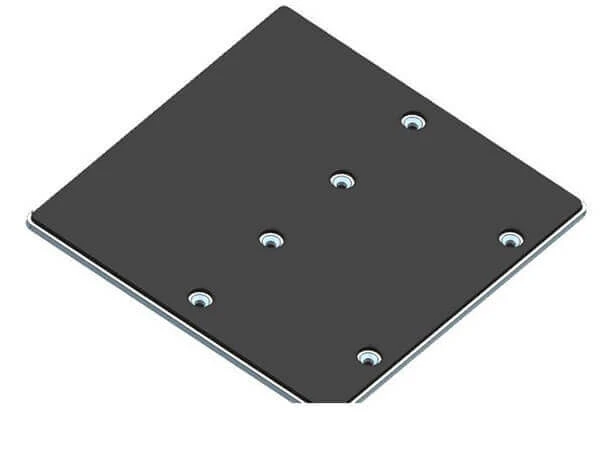

Exact metal parts or components with the tight tolerances needed for completed goods to create complicated. The material is either reshaped, removed, or joined using any combination of fabrication processes.

Three processes for precision sheet metal fabrication:

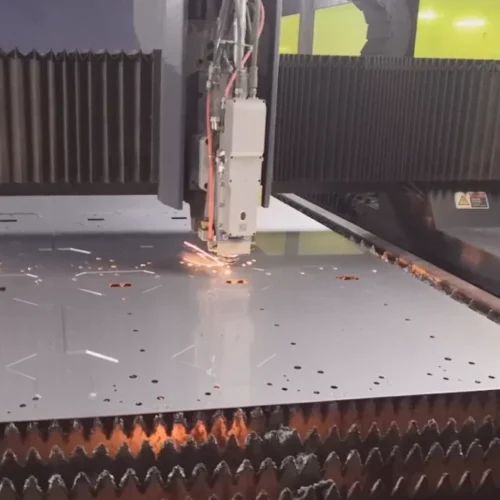

Precision subtractive fabrication. Subtractive fabrication processes, as the name implies, selectively reduce material volume from sheet metal workpieces during a part or product creation. Precision metal laser, punching, shearing, or machining divides the workpieces into smaller pieces. Programmed CNC(Computer Numerical Control) creates complex geometries through subtractive techniques. For instance, a CNC laser cutting machine can precisely and quickly produce sophisticated and detailed custom-designed components in high-volume runs with programmable operations.

Material reshaping is a precision fabrication technique for creating precise parts and goods. Forming is a process that involves molding or shaping material to get the desired result without material loss. The mechanical characteristics of some metals enable plastic deformation from one shape to another. The sheet metal workpiece undergoes plastic deformation to transform it into a desired geometric shape or precise form without compromising the metal’s structural integrity or volume. Standard shaping techniques are bending, drawing, stamping, rolling, and stretching.

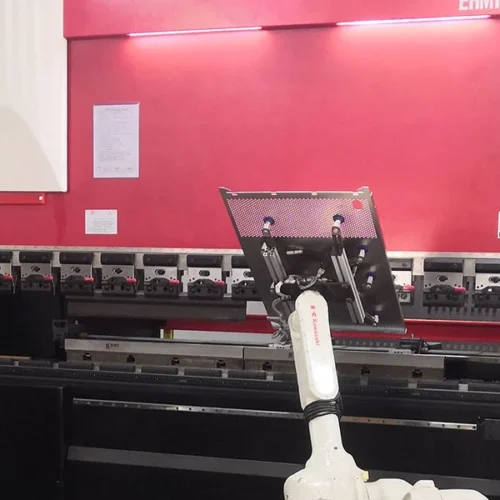

Another fabrication technique used to turn a part or component into a finished product is assembly. Assembly joints the individually produced pieces and components physically using various manual, mechanical, pneumatic, electric, and robotic techniques.

Welding is probably the most well-known method of putting parts together to create a final product. Fabricators can choose various assembly service alternatives to create goods that fit plans and standards.

Precision sheet metal applications

Processes for fabricating precision sheet metal are essential for producing parts and components for numerous industries. Many industrial and commercial products are manufactured using custom fabrication techniques. Custom parts and components for goods, machinery, and buildings can be created by manufacturers using various sheet metal fabricating techniques. For example, electric cabinets are one of Shengen’s main products.

The whole transportation industry—automotive, aviation, aerospace, rail, buses, and seagoing vessels—is at the top of the sectors that depend on precision sheet metal production. Other industries include agricultural commodities, durable goods, energy, tools, and equipment for the food and beverage industry, electronics and telecommunications, and medical devices and equipment. The precision sheet metal fabrication, a typical manufacturing process. It produces an extensive range of consumer and commercial items using a variety of application and techniques.

Fabricators can carefully remove or modify a workpiece using various techniques before putting it together to create a completed product. This process produces highly precise, intricate, and detailed metal parts and components.