The market is full of tools that are supposed to help you get the work done, but how do you know which sheet metal cutting tools to use?

Customers need help deciding which methods suit their needs, and sellers don’t know what to tell their customers. It’s a frustrating situation for all involved.

This guide will walk you through the many different options available and give you practical advice on how to choose the best tool for your needs, along with the best way to cut sheet metal.

Introduction

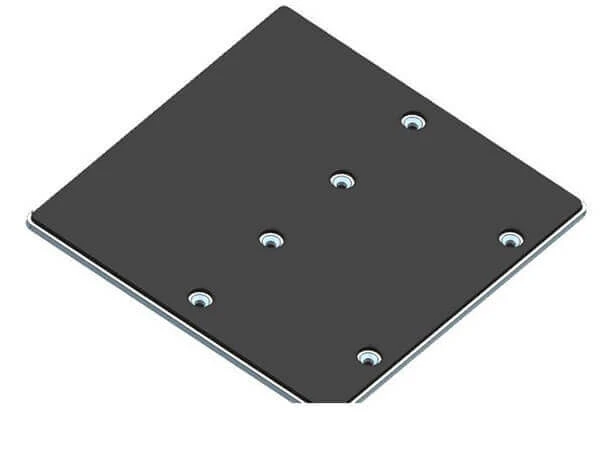

During the sheet metal fabrication process, there are many different sheet metal cutting tools and methods to use. For the most part, these tools and methods are used to shape sheet metal into various forms.

Sheet metal cutting tools are machines used in the manufacturing industry to cut sheets of metal into different shapes. Sheet metal cutting tools are used in automotive, aerospace, construction, and other industries.

There are various types of sheet metal cutting tools. These are utilized based on the desired shape. The common types of sheet metal cutting tools are shears, sheet metal nibblers, snips, and slitting saws.

What is sheet metal cutting?

Sheet metal cutting is a metalworking process that involves using a sheet metal cutting machine to cut metal sheets into pieces. This process is used to make all sorts of things, from car parts to airplane parts and everything in between.

The tools used for this process vary, which depends on what type of work is needed. For example, if you are cutting small pieces of sheet metal, you need to use a handheld shear. If you are cutting larger sheets, you will use an industrial power shear.

Typically, sheet metal is used in the manufacturing of electrical, automotive, and medical products. Hence, an effective sheet metal cutter becomes important. With the right sheet metal cutting tools, you can cut sheet metal quickly and easily.

Many different processes are used to cut sheet metal. Knowing the differences between each is essential so that you can choose the best sheet metal cutting tools for the job.

There are four basic sheet metal cutting tools.

1. Shears

2. Saws

3. Plasma Cutters

4. Angle Grinders

Some common sheet metal cutting tools

Using an effective tool for cutting sheet metal and applying proper methods is important to make sure that you get the results you want. Some common sheet metal cutting tools and methods include shears, saws, and snips.

Sheet metal shears

Shearing is a mechanical process of cutting sheet metal in straight lines. The shearing process is most commonly performed on a shear machine. These machines can be electric, hydraulic, or pneumatic.

They can be used for cutting metals such as steel or aluminum. Shears are typically designed for cutting sheets used in the construction and automotive industries.

Sheet Metal Snips

Whether you’re a beginner or an experienced metalworker, sheet metal snips are great sheet metal cutting tools for cutting sheet metal, and they can help you work more efficiently. They’ll also help you avoid damaging your sheets.

There are many types of snips available. The best ones will be designed to handle the metal thickness that you are cutting. Some models of snips are designed to cut in straight lines. At the same time, some others are created to cut in curves.

These are made of any alloy and come in different shapes as well as sizes. They’re an excellent choice if you want to cut metal but do not want to use power tools.

Sheet Metal Saws

Among the many sheet metal cutting tools used in the metal industry, sheet metal saws are among the most popular. They cut through a variety of materials, including galvanized iron, steel, and galvalume metal plates.

Generally, sheet metal saws are either electric or handheld. The electric version is ideal for making straight cuts.

When cutting sheet metal, keep the material cold. Remember to wear protective work gloves. This will help protect your hands from the heat and chemicals that are used during the cutting process.

Four Sheet Metal Cutting Methods

Among the many metal cutting methods, there are four that you may want to consider: Plasma cutting, EDM cutting, laser cutting, and waterjet cutting. Each of these methods has its benefits and drawbacks, and you should make a proper decision about which one is best for your needs.

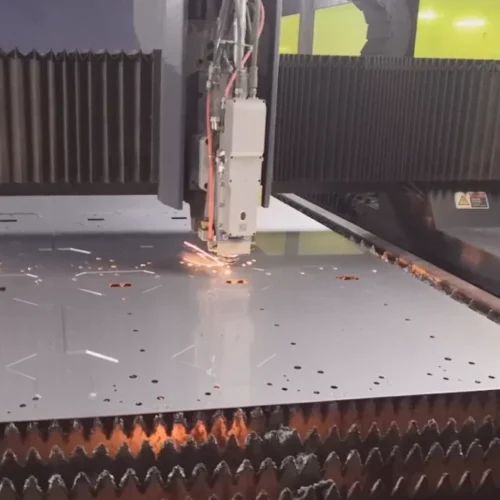

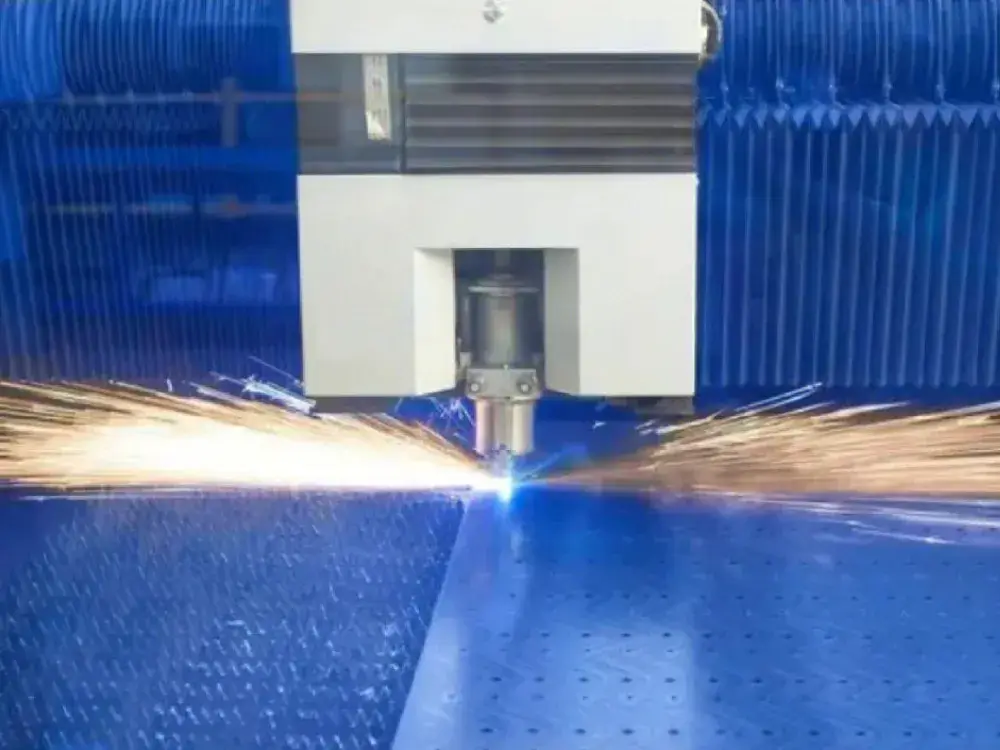

Sheet metal laser cutting

Using an sheet metal laser cutter is a great way to create clean, straight cuts. This process is an excellent method to cut intricate details and get a beautiful finish.

Laser cutting is a contactless, thermal process. It means the heat source is a laser. Typically, a laser beam is focused through a high-quality lens on the work zone.

After amplification, the beam exits through a series of mirrors. It is important to remember that the narrowest part of the focused beam is only about 0.0125 inches (0.32 mm) in diameter.

While laser cutting has many benefits, there are also some disadvantages.

- First, the heat generated by the process can warp and distort parts.

- The laser also can be susceptible to back spatter, which can damage the focusing optics.

- Another disadvantage is the oxidized layer left on the cut surface.

- Also, while laser cutting offers excellent speed and accuracy, it is not the cheapest method.

- It also requires an experienced machinist.

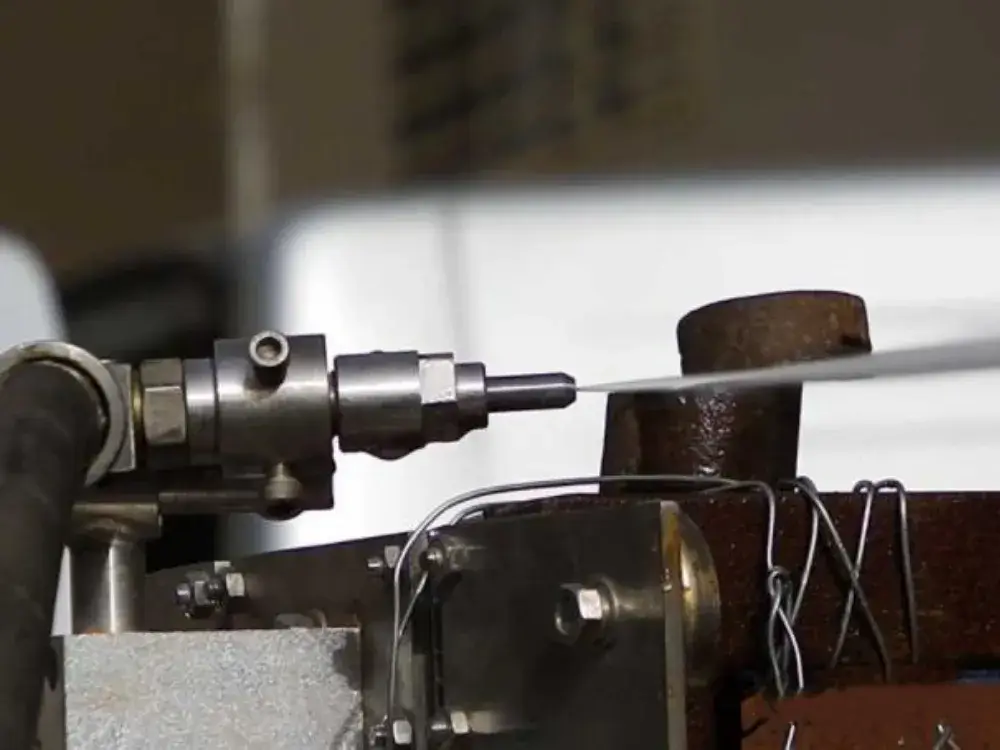

Waterjet cutting

Whether you are looking for industrial water jet cutting or precision water jet cutting, there are many advantages to choosing this method of metal fabrication. The process is less expensive and less wasteful than other methods and is eco-friendly.

Water jet cutting produces high-quality parts with smooth edges, which has several benefits, including

- High cutting accuracy

- Efficiency

- Cost-effectiveness

- Adaptability

It is possible to cut a variety of materials with precision water jet cutting, including steel, aluminum, plastics, rubber, wood, and foam. It is also suitable for cutting holes, tight radii, and irregular shapes. This type of cutting is also eco-friendly because it does not generate toxic fumes or greenhouse gases.

Another advantage of water jet cutting is that it does not require post-processing or secondary finishing.

EDM cutting

Unlike laser or plasma cutting methods, EDM uses high-voltage sparks to cut metals. This process is used to produce ultra-precise components. It is also used in aerospace, medical and tool industries. It is becoming a common method for creating production parts.

EDM uses a special wire called an electrode. The electrode is made of a conductive metal. It may be made of brass, graphite, or copper. To ensure that the electrode is not touching the workpiece, a servo motor is guided in the desired path.

Electrical discharge machining is a newer method of metal processing and has the following benefits:

- It is more effective for machining tough materials.

- The process also requires little bulk heating, leaving no residual stresses.

- It is error-proof and highly reproducible.

- It can produce fine features, small apertures, and internal cuts.

- It is also a good process for thin machining materials.

The process allows for a smooth surface finish and is ideal for drilling through hard or complex geometries. The dielectric fluid, usually deionized water, helps control the process and helps remove material left behind. It can also control the amount of heat produced during the process.

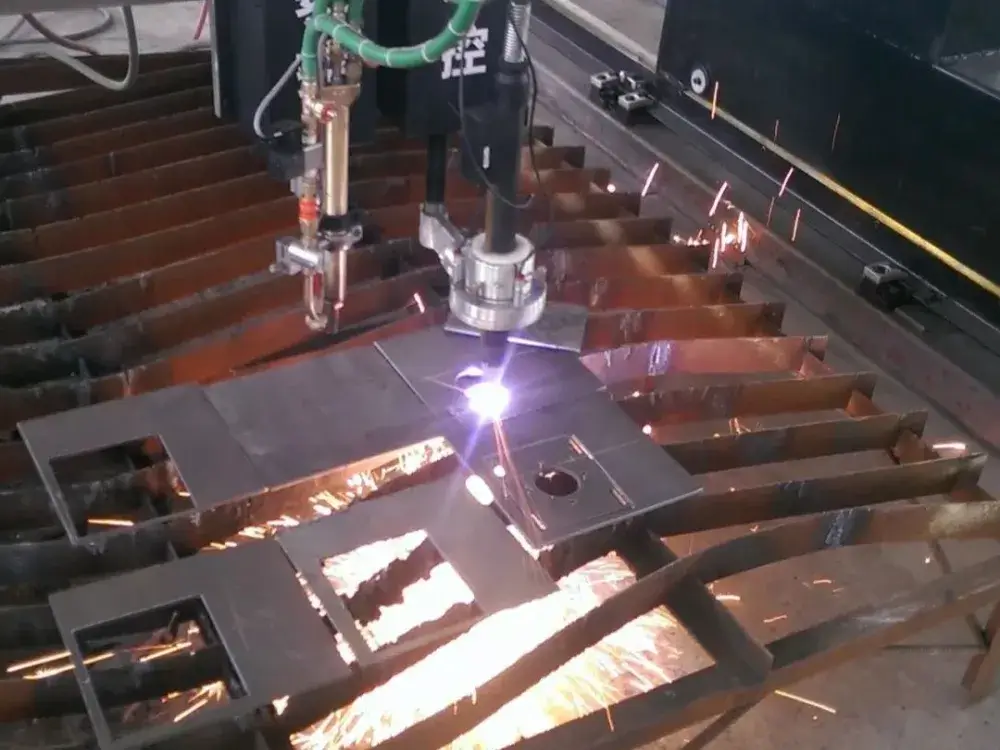

Plasma cutting

Using plasma cutting on sheet metal is an excellent way to cut through medium and thick gauges of metal. Plasma cutters are used in various industries.

- It produces accurate, smooth cuts and has less on-the-job injury than other metal-cutting methods.

- It is also more portable

- It produces a sharper edge compared to oxy-fuel cutting.

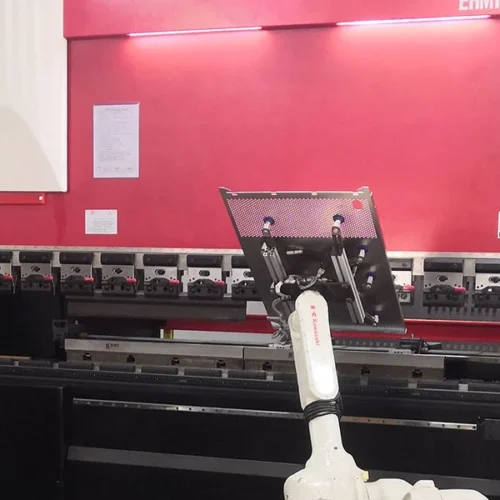

- It can be used with CNC machines, which provide accuracy and repeatability.

Plasma cutting systems use advanced CAM software to analyze part drawings, identify the best lead-ins and outs and optimize the cutting parameters. This improves accuracy and increases throughput. It also affects the cost of operating the cutting machine and the quality of the cut part.

Plasma cutting uses hot plasma for cutting through the metal. It is especially useful for metals that conduct electricity. This type of cutting is ideal for machining large sheet metal parts, such as consoles and enclosures.

It is also useful for tubing, brackets, and tube assemblies. Plasma cutting is often used in the aerospace and electrical equipment industries.

What Should You Look For When Cutting Sheet Metal?

Whether you are new to cutting sheet metal or you are an expert, you may want to know how to make the task a bit easier. There are several things you should be aware of, from what type of material you should be cutting to which type of tool will best fit your needs.

Make sure you wear appropriate safety gear.

Using personal protective equipment ensures your safety while cutting sheet metal. It also helps prevent accidents outside of the actual cut.

Safety equipment for cutting sheet metal includes a face mask, safety glasses, safety gloves, and protective footwear. Each piece of equipment must be properly sized and be suited to the hazards associated with the activity.

You should avoid wearing loose clothes or any piece of jewelry that could get tangled in the machinery.

You should also wear a fire-resistant apron. Leather shoulder covers should be worn for overhead welding operations.

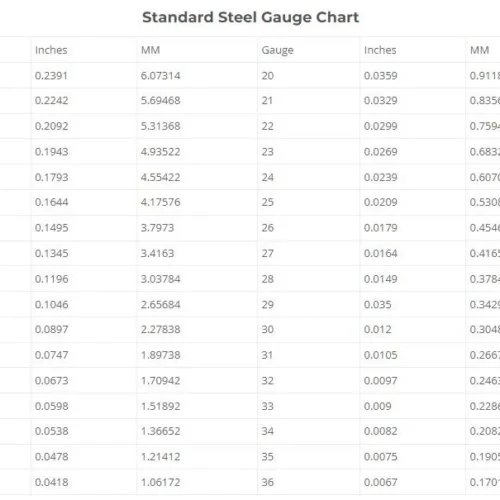

Select the right blade for the right material

When cutting sheet metal, choosing the proper blade for any material can make a considerable difference in the overall efficiency and quality of the job. But choosing the wrong blade can also cause the workpiece to warp, bend, or shatter.

To prevent these hazards, it’s important to choose a blade that matches the material, the type of saw, and the type of cutting job.

There are three types of blades designed for metal cutting. These are toothed, slicing, and regular-tooth. Teeth per inch (TPI) is an important measure of the blade’s aggressiveness. A fine blade has more teeth per inch than a coarse blade. If you’re cutting thin sheet metal, a fine blade with a TPI over 18 is necessary.

If you’re cutting a soft non-ferrous metal, such as aluminum, a high-speed steel blade is the best choice. Carbon steel is another good choice for softer materials.

If you’re cutting thicker lines, a hardback blade is the best choice. But a hybrid blade can also be useful. Hybrid blades typically have a mid-range tooth count. These blades create clean cuts while reducing vibration.

Select the correct hand tools for cutting sheet metal.

If you’re cutting sheet metal, you’ll need to select a metal cutting tool that’s suitable for the job. For example, if you are cutting thick, corrugated metal, you’ll need to use a saw or compound snips.

Alternatively, you can use a cut-off tool for thinner metal. No matter which tool you are using, always ensure that you are wearing safety glasses and a face mask.

Conclusion

Using the right sheet metal cutting tools and techniques is key to a successful sheet metal project. Some techniques are more effective for certain applications, and others are not. Knowing which one is right for your work can be a money and time-saver.

You can cut sheet metal in various ways. In some cases, you will need to use hand tools to achieve the best results. In other cases, you may need to use a power tool. Using a power tool can be a much more efficient method of cutting sheet metal. https://shengenmfg.com/ can help you make a wise decision about your sheet metal cutting needs.