Our Sheet Metal Folding and Forming Service

Sheet metal fabrication is a time-consuming, expensive process. To get the best quality, you have to outsource sheet metal folding services that can produce high-quality products for your business.

There are plenty of hacks and tricks when it comes to cutting corners with sheet metal fabrication, but none of them will last longer because they’re all low quality and do not solve your problems.

Our sheet metal folding company offers sheet metal folding and forming services, so you don’t have to spend hours or days finding a quality company to work with.

We take pride in our Sheet metal folding and forming services and go the extra mile to make sure your products for your customers are perfect both in engineering and aesthetics.

Suppose you have a small business and you want to improve your production; you may want to look at hiring our sheet metal folding and forming services to produce parts for you. This is an excellent way to increase your profit and decrease your inventory costs.

Are you looking for a qualified sheet metal fabrication subcontractor? If it’s Yes, Shengen will be your top choice!

Sheet Metal Folding and Forming Service Overview

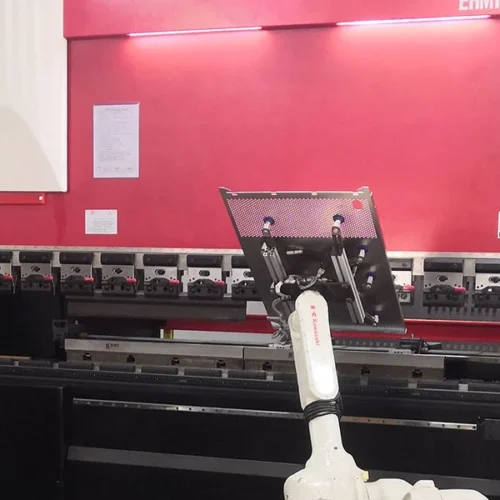

Sheet metal folding and forming service is a great option for manufacturing a wide range of products. It also happens to be among the most reliable forming procedures available for large-scale parts. The procedure is highly automated in factories and metal workshops.

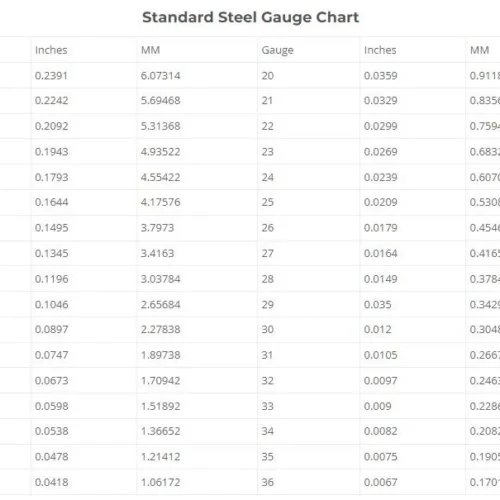

When choosing a forming technique, it is important to consider the requirements of the project. A consultation with an expert can help you determine which material and process are best suited for your needs.

Most modern fabricators have a variety of forming options. Each sheet metal folding method is unique and has its benefits and disadvantages. However, there are a few basic considerations to keep in mind.

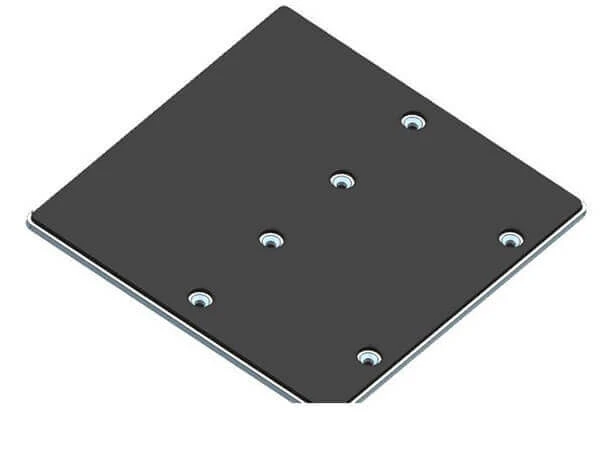

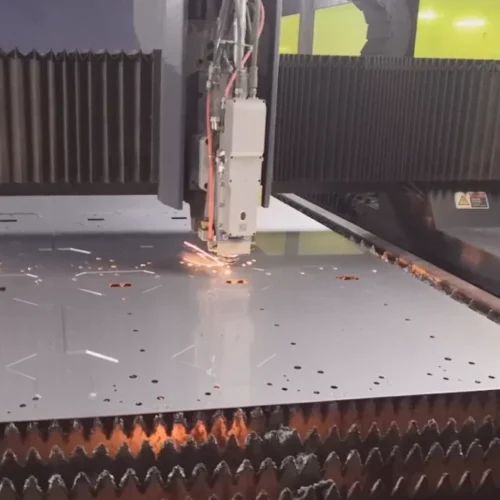

Sheet metal forming is among the most important manufacturing processes. This procedure is effective in creating geometrically accurate components with minimal waste of material.

However, Sheet metal folding and forming can be expensive for small companies. Small firms must determine their optimal forming parameters, tune the process, and manufacture a series of tools.

Advantages of Sheet Metal Folding

A sheet metal folding and forming service offers several benefits to businesses. These include:

- Sheet metal folding provides Increased speed and flexibility

- Sheet metal folding provides better accuracy

- Sheet metal folding offers lower costs

- The Sheet metal folding process allows for easy assembly and is capable of producing large quantities of parts

Sheet metals are lightweight, durable, and resist corrosion. This makes them ideal for outdoor projects. In addition, they are easy to handle and can be shaped into various shapes and sizes. Besides being light, they are strong and can handle high pressures.

The process can be done on a wide variety of materials and is very flexible. The ability to bend sheet metal into a wide range of shapes and sizes is one of its greatest strengths.

Sheet metal folding is done with a machine called a sheet metal folding machine. The process is used in the production of cars, aircraft, and other products. The machine has two sets of rollers that fold the sheets by using a series of levers, one set to pull the sheet and one set to push it.

Advantages of Sheet Metal Forming

Sheet metal is a material that is used in a wide range of industries. It is malleable, durable, and able to withstand extreme temperatures. It is also corrosion-resistant. This makes it a perfect choice for outdoor projects.

Metal is more affordable than other materials. Since it is a durable and flexible material, it is a cost-effective solution.

- Sheet metal fabrication uses automated machinery to produce high-precision parts

- It can help you design and create prototypes more quickly

- You can save on repairs and upgrades

Sheet metal can be formed into many shapes and sizes. You can also add finishing processes to increase durability and resistance to moisture or corrosion. In addition, sheet metal is easy to inspect.

Sheet metal forming uses the latest CAD/CAM technology, which improves accuracy. For a single part, the process can be as accurate as 0.0005 inches.

If you need to manufacture large volumes of sheet metal, you can opt for roll forming. This process produces tight tolerances and can accommodate spring back. However, the tooling costs may be higher than other forming services.

Sheet metal fabrication is an efficient and cost-effective way to produce items. Many companies use CNC punch presses and other equipment for sheet metal forming. It is also possible to create holes in the material with a laser cutter.