Depending on the material and tools you use to cut sheet metal, the process can be complex, tedious, or simple. Cutting sheet metal requires that you know the properties of sheet metal. There are Sheet metals that are thick and have rigid strength. Some are very flexible that can be reshaped using hand or minimal sheet metal cutting tools.

Cutting sheet metal achieves a specific shape or dimension through cutting-edge sheet metal. Forces are applied to cut sheet metal through shearing or die blades capable of forcefully cutting through the material. Cut sheet metal by placing the material between two parts of the procedure. The material on which the metal sheet is placed has two sides; the upper side is the punch, and the lower side is the die.

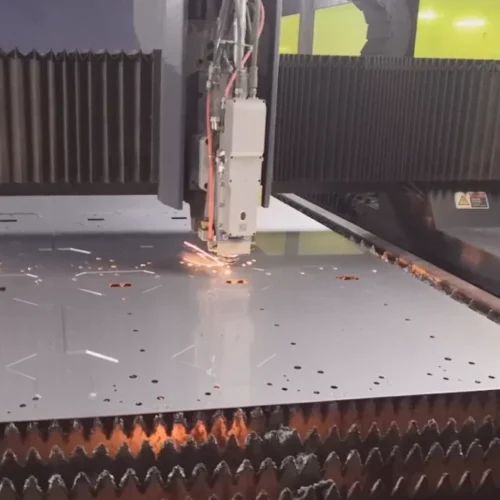

How to cut a sheet of metal is a skill or act that should be appropriately mastered whether you are a metalsmith or want to cut sheet metal at home without requiring the services of anyone. On the look, to cut sheet metal may be simple. However, to cut circles in sheet metal or cutting edge sheet metal in a clean, straight, and accurate manner requires practice and a guide. In this article, we will take you through the process to cut sheet metal the best way using sheet metal laser cutting and other tools.

Different operations in sheet metal cutting

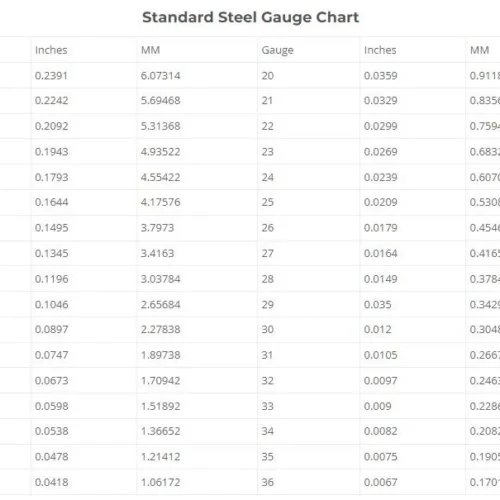

some different operations or procedures can be followed to cut sheet metal depending on what you want to cut and for what purpose. Before proceeding, consider the thickness of what you want to cut. In cutting sheet metal, several processes are involved.

Punching:

Punching procedure is one of the simplest operations to cut sheet metal. It involves cutting out a small part of the sheet metal, and it has different variations. The variations that are involved in punching are;

Piercing – this involves creating a slot or a single hole in the metal sheet by extrusion. By extrusion, you combine forming and cutting to give a little or no scrap of the sheet metal.

Lancing – a single strike is used to shear and bend a particular piece of sheet metal to get different forms, such as tabs, louvers, vents, and many more.

Notching – this process is exclusive to sheet metal edges for creating notches.

Slotting – this is used to cut a rectangular slot in sheet metal using a rectangular tool.

Nibbling – it combines different overlapping punches to get different kinds of figures. Nibbling is often used in creating complex shapes.

Perforating – many relatively small holes are generated using this method. The holes generated are close to each other on the metal sheet.

Blanking:

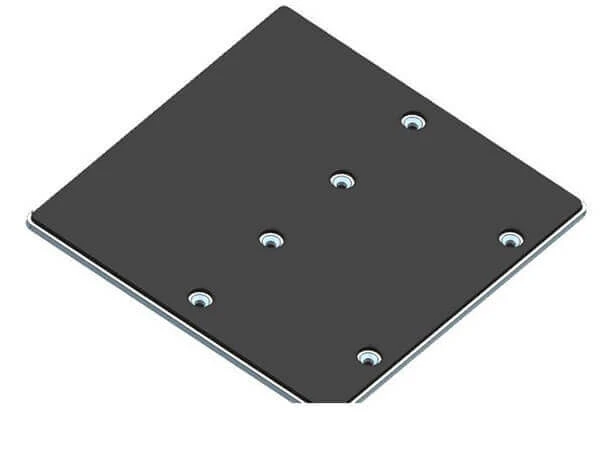

This operation is used to create small details. And this is achieved by cutting the enclosed part of the sheet metal by applyinga massive shear force to the sheet metal piece. Blanking can be used to cut sheet metal for creating automotive components, plane washers, small gears, and many more.

Shearing:

This is used to cut sheet metal in a straight line or angular form. This method helps cut large metals into smaller ones.

Slitting:

This process helps cut sheet metal pieceswith two opposing circular blades. With it, straight and curve lines can be created. Slitting is essential in cutting sheet metal, and it helps create metal pieces of specific width for other machines to cut through adequately.

Trimming:

This process helps cutborders of the workpiece from excess metal materials. Trimming always comes towards the final part of the sheet metal manufacturing process.

Deburring:

This process is also used to removeexcess materials from sheet metal when the workpiece is nearing completion or has been completed. The burr on the piece will be removed to get smooth edges. The process involved is through machinery, unlike trimming, which demands hand tools.

Things required to cut metal sheet

Sheet metal cutting entails a different approach to it. It can be done using hand, master sawing, or a sophisticated machine. Some things are needed to cut sheet metal using the most basic method to get the work done.

- Preferred Sheet Metal: if you are learning to cut sheet metal for the first time, usea cheap material to practice with, such as brass and copper.

- Jewelers saw frame: this adjustable frameis handy in use. The frame can be adjusted to reuse the blade when the blade is snapped.

- Saw blades: saw blades come in different sizes, and you can choose one based on the sheet metal thicknessto cut. Also, ensure you have a stock of the blade.

- Other things needed to cut sheet metal are the steel ruler and square, marker, saw blade lubricant (for a clean cutting), bench peg, and anvil (this will help to station the metal piece and make the cutting straight.

How to cut metal straight through DIY

Once you have gotten all the basic things needed for the cutting, the next thing is to follow the guide on how to cut sheet metal perfectly and in different shapes.

Fix the saw blade to the frame:

To fix the saw to the frame, loosen the nuts on the frame at each end and fix the blade in it. While fixing the blade, ensure it is in the right direction for cutting. Once you observe that the direction is suitable for the cutting by running your hands on the blade, tighten the nuts at each end of the saw. To check the tightness of the blade, pluck it like you are doing for a guitar string. When it gives an excellent ting sound, it indicates it is suitable for use.

Mark the sheet metal:

Before you cut sheet metal, you should know the shape you want to cut, if it is a square or rectangular shape. To cut any of these shapes, you need to work with perfectlystraight lines. Mark the lines to cut on the sheet metal to what you desire accurately.

Use the bench peg:

Using the bench peg makes the sheet metal be placed in a comfortable and central position. While setting the metal sheet on the peg, let the middle notch of the peg fall over the line. With this set, cutting through the sheet metal will be clean and smooth.

Create a notch in the metal sheet:

Making the first cut in the sheet metal is always tricky and can mess up the whole process if care is not taken. To avoid this, create a notch in the metal sheet with a gentle forward stroke of the saw. With the small hole created, you can start sawing using slight Keep on sewing the metal along the line you have on the metal. As you are sawing, use the fluid sawing motion movement together with the weight of your hand to initiate the cutting. As you are cut through the sheet metal, always dust the small shavings away from the surface. In the cutting process, if you observe that the blade not moving smoothly, lubricate it to continue with the cutting.

How to cut a hole or circle in sheet metal

How to cut a hole in sheet metal is less complicated if you have practiced and mastered to cut sheet metal in a straight line. To cut a circle in sheet metal, this is a handy procedure to follow.

- Make a loose grip onyour saw and not a tightened one so that the saw can easily move on the sheet metal.

- The blade should not be moved forward to get a perfect circle, like cutting a straight line. Instead, the saw should be held upright, moving it up and down to do a perfect circle cutting.

- The best way to cut sheet metal at the curved edges or corners that may require turning the saw is to allow the saw to be at the same spot. While on the spot, move it up and down. By keeping the saw still, you can rotate the sheet metal.

- Cut sheet metal circles may not have a smooth curve. When this happens, get back to the piece with your saw, placing the side of the blade on the point that is jutting out, which requires reshaping. Jog the blade up and down gently on the side that needs to be smoothened to have a perfect circle.

Conclusion

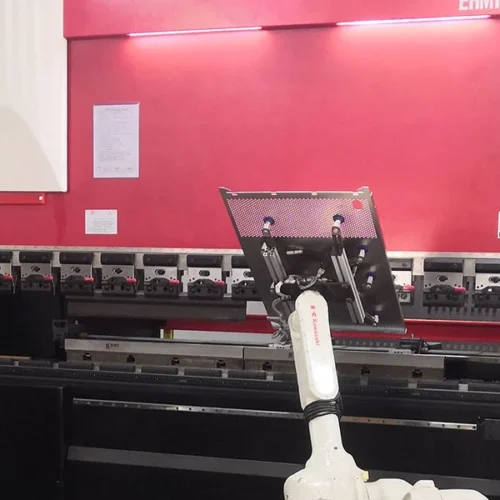

To cut sheet metal the best way, you must master the skill to perfect it through DIY. There is no complexity involved. With the right tools and this guide, you can scale through the process. However, if you are looking forward to how to cut metal sheets in a more advanced way using machines, the process involved and the tools required are different from cutting sheet metal at home. For instance, to cut sheet metal in an advanced way, you will need sheet metal cutting tools like grinder and cut-off wheels, circular saw blades, band saws, snips, chisel and hammer, Beverly throatless shears, and many more. And this may require a lot of money and effort to begin with. With sheet metal cutting at home, you can achieve any shape you want that will meet up perfectly with its use without defects.