Depending on the material and tools you use to cut sheet metal, the process can be complex, tedious, or simple. Cutting sheet metal requires that you know the properties of sheet metal. There are Sheet metals that are thick and have rigid strength. Some are very flexible that can be reshaped using hand or minimal…

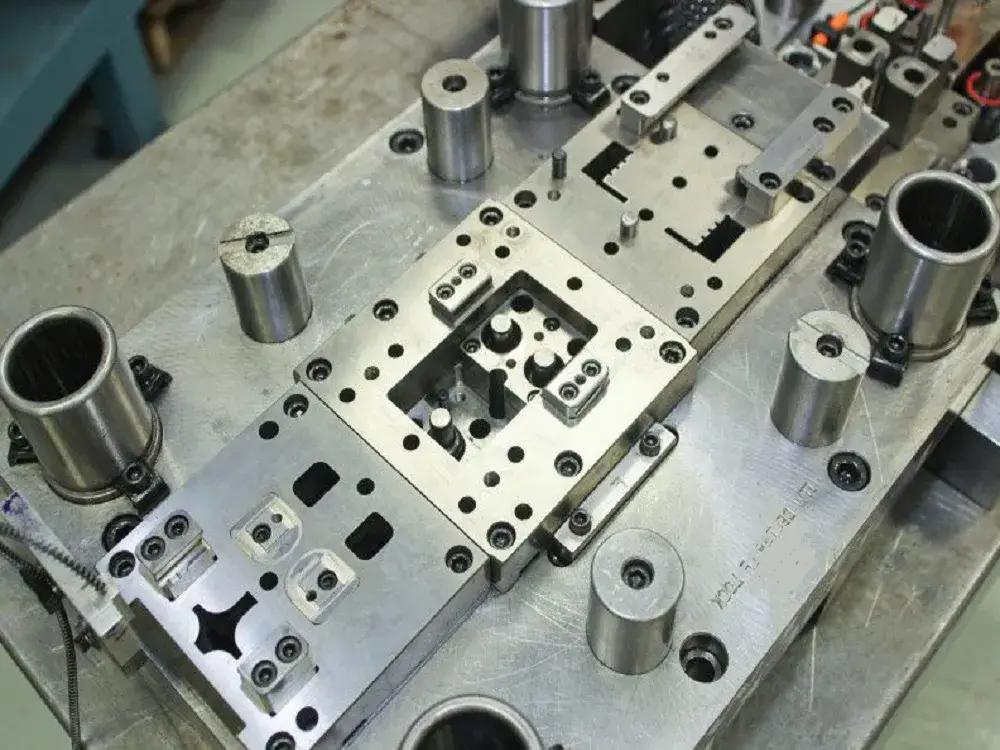

Tool and die is a unique field in the manufacturing industry. It entails creating gauges, cutting tools, dies, fixtures, jigs, and other related tools that can be used in the manufacturing industry. Tool and Die are often used interchangeably to mean the same thing. Although, there are some little functional differences between the two terms….

3D Printing with metal can be difficult and expensive. Traditional metal fabrication processes are time-consuming, require specialized equipment, and are often cost-prohibitive. Can 3D Printers Print Metal? Yes! With the latest 3D printing technology, it is now possible to produce 3D objects with metal materials. In addition, it allows for faster prototyping and production of…

Welding sheet metal can be complicated if you don’t have the right tools and techniques. You could end up with weak welds, or worse; you could cause damage to the sheet metal. This in-depth guide to welding sheet metal will provide you with everything you need to get going. Then, with our help, you’ll be…

There are dozens of machine processes used in manufacturing companies where raw and semi-raw materials create products. CNC turning and milling are among the most commonly used methods; like most machining processes, they require a machine.

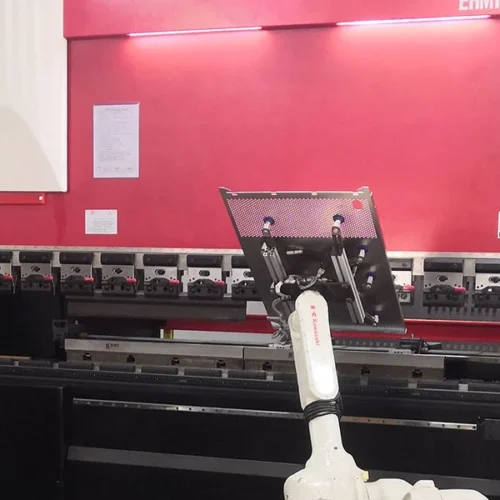

Sheet metal bending is an act that requires creativity and some level of accuracy to get the right shape to fit its use. Sheet metals are used for various purposes, such as car antibodies, building truck beds, etc. Some homeowners use steel metal for perimeter fencing around their houses or yard. As rewarding as sheet…

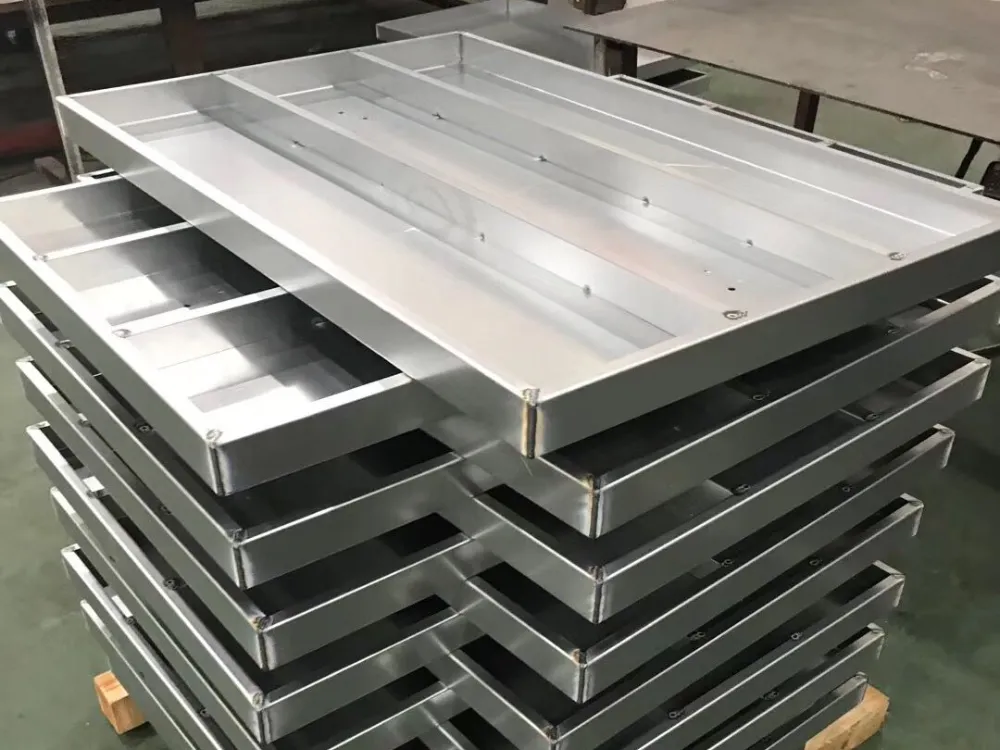

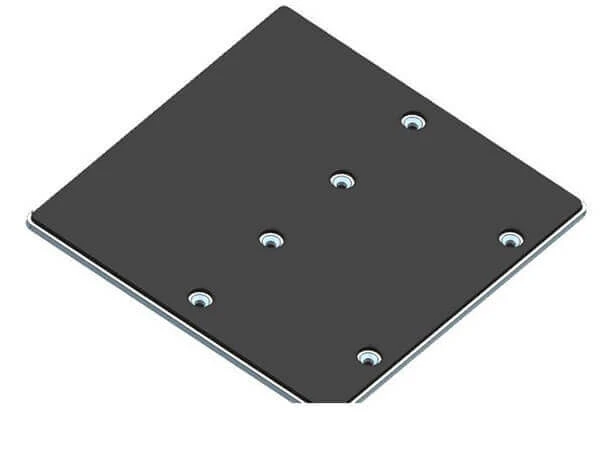

Custom sheet metal fabrication is vital for manufacturing with a huge list of methods and usable metals. In addition, metal is essential in how people operate in every household and working area. Metal is a stabilizing component that makes all of today’s conveniences possible, from light fixtures and appliances. Despite its popularity, it is vital to…

The market is full of tools that are supposed to help you get the work done, but how do you know which sheet metal cutting tools to use? Customers need help deciding which methods suit their needs, and sellers don’t know what to tell their customers. It’s a frustrating situation for all involved. This guide…

What is Metal Powder Coating? Powder plays an essential role in various items and accounts for about 15% of the market for industrial finishing. Since it was first used as a dry finishing process in North America in the 1960s, powder coating has experienced enormous growth in acceptance. For a high-quality, long-lasting finish, more and…

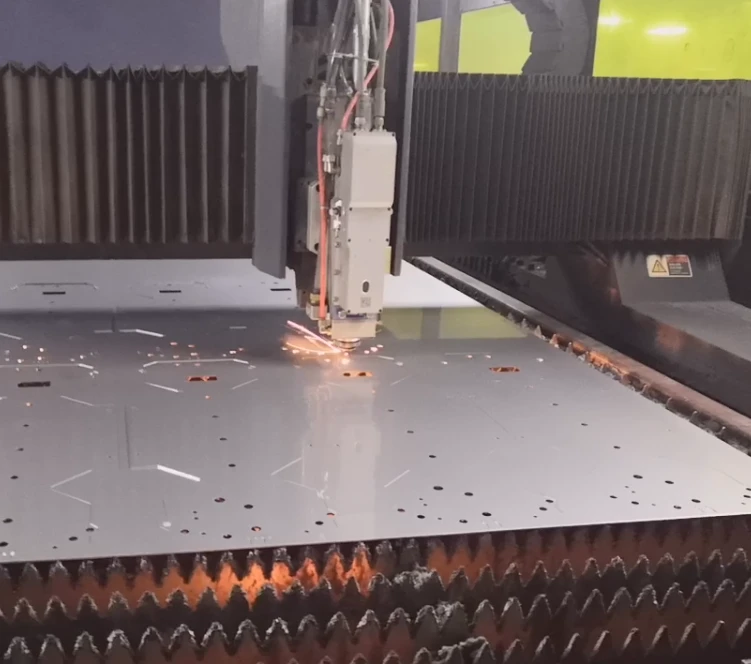

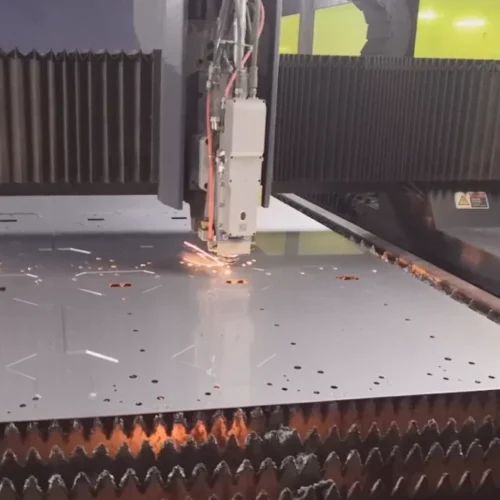

How to cut sheet metal? One of the four methods of fabricating sheet metal is cutting. The most common sheet metal techniques are laser and water jet cutting. What is laser cutting? Laser cutting is a thermal process that utilizes a high-power light beam(i.e., a laser cutter), which melts the materials apart. Laser cutting is…

- 1

- 2